Mapping Li Distribution in Battery Anode Cross-Sections Using Broad-Beam Ion Milling and FIB-SIMS

- Abstract number

- 307

- Presentation Form

- Poster

- Corresponding Email

- [email protected]

- Session

- Poster Session One

- Authors

- James Gott (1), Eleni Fiamegkou (1), Louis Piper (1), Geoff West (1)

- Affiliations

-

1. WMG, University of Warwick

- Keywords

Li-ion Battery, Anode. BBIM, FIB, SIMS, Airless

- Abstract text

The development of batteries with improved capacity and charging time continues to be dominated by Li-ion batteries [1,2]. In understanding the performance of new Li-ion battery chemistries, being able to measure the spatial distribution of Li in cross-sections of electrodes is of great interest. Two of the largest barriers to these kinds of studies are: 1 - being able to protect the sample from air exposure and 2 – being able to reliably detect Li.

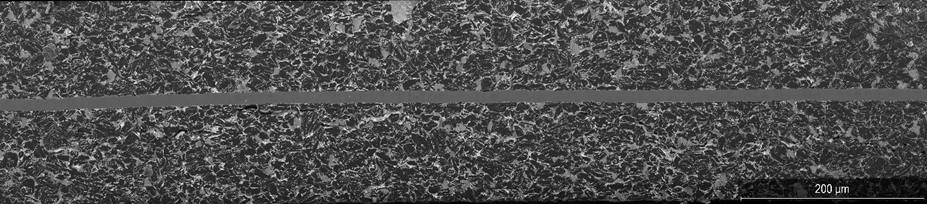

This work demonstrates a workflow that produces high quality cross-sections of calendared anodes (with a polished area up to 1mm wide, see Figure 1) using Ar broad-beam ion milling (BBIM) which can then be studied in a Ga focused ion beam (FIB) with FIB-SIMS (secondary ion mass spectroscopy) to map Li distribution. The workflow presented is a completely airless process. A piece of calendared anode sample is prepared inside a glovebox, transferred via an air-protected capsule to a BBIM, transferred back to the glovebox, and finally transferred to a Ga FIB using an integrated airless transfer system.

By utilising the airless process outlined, Li maps can be obtained from anodes at various state of charges (SOCs) and temperatures for specific time intervals, allowing for comparisons of Li distribution at different calendaring stages. This is currently the only direct method of unambiguously detecting Li in these types of samples in a scanning electron microscope (SEM)-type platform and allows changes in the Li distribution to be determined as a function of cycling conditions. The use of the Ar BBIM minimises contamination from the primary ions and the use of a continuously rocking stage avoids artefacts (curtaining) commonly seen in conventional FIB systems (Ga and Xe plasma). The size of high-quality cross-section produced by the BBIM also allows for greater statistical studies into any variations of features observed.

Figure 1 – A secondary electron SEM image of a carbon graphite anode cross-section prepared by BBIM. The polished area is approximately 1mm wide.

- References

[1] Fast Charging of Lithium-Ion Batteries: A Review of Materials Aspects, M. Weiss, R. Ruess, J. Kasnatscheew et al. Advanced Energy Materials, 11, 2101126 (2021)

[2] A Comprehensive Review of Li-Ion Battery Materials and Their Recycling Techniques, H-J. Kim, T.N.V Krishna, K. Zeb et al. Electronics, 9, 1161 (2020)