THERMAL STABILITY OF NICKEL NANOPARTICLES WITH TITANIUM OXIDE SHELLS.

- Abstract number

- 367

- Presentation Form

- Poster & Flash Talk

- Corresponding Email

- [email protected]

- Session

- Poster Session Two

- Authors

- Miroslav Cieslar (1), Lucia Bajtošová (1), Jan Hanuš (1), Rostislav Králík (1), Barbora Křivská (1), Jan Fikar (2)

- Affiliations

-

1. Charles University, Faculty of Mathematics and Physics

2. Czech Academy of Sciences, Institute of Physics of Materials

- Keywords

Core-shell nanoparticles, in-situ electron microscopy, nickel, sintering, thermal stability

- Abstract text

This study presents results from the in-situ annealing of nickel nanoparticles prepared by a gas aggregation source. Their significant sintering could occur at elevated temperatures. A thin titanium oxide shell could enhance the resistance to sintering and shift the coarsening of particles to higher temperatures.

Metallic nanoparticles are of great interest because of their unique electronic, catalytic, optical, and magnetic properties, often controlled by their characteristic dimension. For example, in ferromagnetic materials it is the size of a single-domain structure. However, significant sintering could occur at elevated temperatures resulting in the growth of the diameter of nanoparticles and a modification of their properties. The thermal stability of ferromagnetic nanoparticles could be improved by their embedding in a non-magnetic matrix or by their coating with a thin shell layer.

The production of metallic nanoparticles became accessible with improved vacuum sputtering gas aggregation techniques [1,2]. The addition of supplementary magnetrons enables the production of core-shell particles. Ni nanoparticles with a size ranging from 5-10 nm were prepared, and part of them was coated with a 1-2 nm thick Ti layer. Oxidation of the Ti layer occurs in the air due to a high Ti reactivity with oxygen, thus forming a protective oxide layer [3].

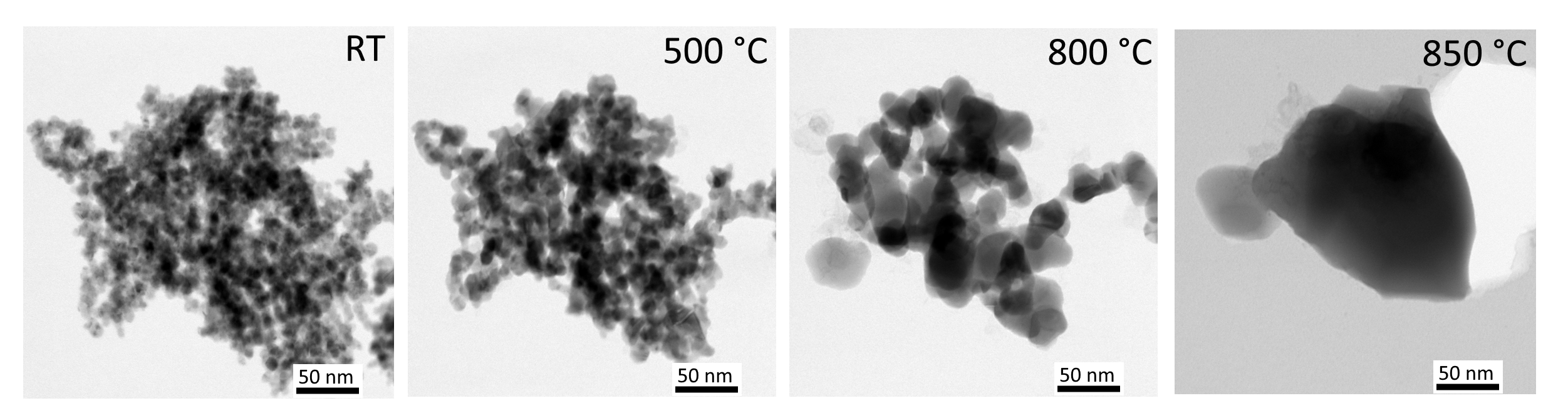

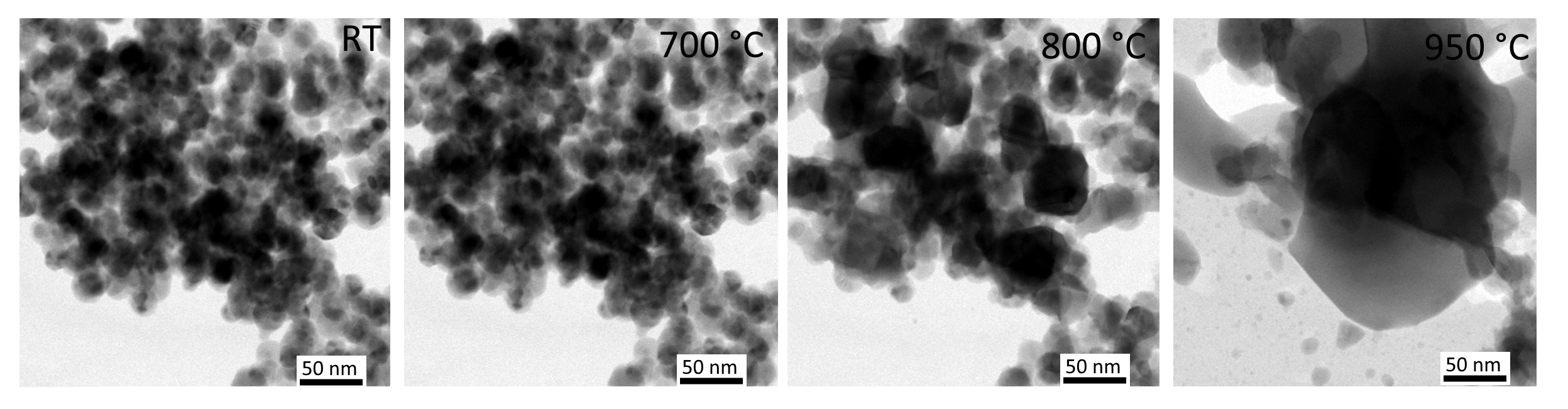

Both types of nanoparticles were annealed in-situ in the electron microscope up to 900 °C. The first significant sintering occurs below 500 °C in pure Ni nanoparticles, while the shell-protected ones are stable even at 700 °C. Nevertheless, at 800 °C, the oxide layer also loses its protective capacity, and coarse particles start to form.

Figure 1: Sintering of Ni nanoparticles during in-situ annealing.

Figure 2: Evolution of shell-protected Ni nanoparticles during in-situ annealing.- References

[1] A. N. Banerjee, R. Krishna, and B. Das, Applied Physics A 90 (2), 299-303 (2007).

[2] Y. Huttel, Gas-Phase Synthesis of Nanoparticles (Wiley‐VCH, 2017).

[3] J. Hanuš et al., Journal of Physics D: Applied Physics 50 (47) 475307.