Electron Probe Microanalysis (EPMA) of Complex Niobium Silicide Alloys.

- Abstract number

- 287

- Presentation Form

- Poster

- DOI

- 10.22443/rms.mmc2023.287

- Corresponding Email

- [email protected]

- Session

- Poster Session Three

- Authors

- Mr Stuart Creasey-Gray (2), Mr Joseph Weeks (2), Dr Claire Utton (2), Dr Jonathan Fellowes (1), Dr Ian Ross (2)

- Affiliations

-

1. University of Manchester

2. University of Sheffield

- Keywords

EPMA quantification, boron analysis, niobium silicide alloys, turbofan, jet engines

- Abstract text

Introduction

Niobium silicide-based alloys are a promising new material to replace nickel-based superalloys for use in turbofan jet engines to improve efficiency, where material operating conditions can reach temperatures in excess of 11500C. The main issue facing niobium silicide-based alloys is their poor oxidation resistance, which is primarily a result of the niobium solid solution phase (Nbss) having poor oxidation resistance and a high oxygen diffusivity.

Through additions of both boron and germanium to a previously studied bulk alloy, Nb-18Si-24Ti-5Cr-5Al (KZ5 [1]), the oxidation resistance of this alloy system is yet to be optimised. Boron and germanium can be substituted into amorphous SiO2, the formation of an amorphous B-Ge-Si-O layer is a possible route to acceptable oxidation resistance [2].

However, the effect these additions have on the microstructure and phase compositions of the alloy must be well characterised if boron and germanium containing niobium silicide-based alloys are to be developed further. Boron presents particular difficulty when quantitative data is required, as it is a light element and energy dispersive spectroscopy (EDS) does not possess the spectral resolution required to differentiate low energy peaks.

Of concern to this study is the macro and micro segregation of elements across the produced ingot, and how this macro-micro segregation is altered by heat treatments and different elemental additions. Any future component made for aerospace application will presumably require reliable mechanical properties and therefor a homogeneous microstructure. The degree to which the composition of the alloy varies across an ingot and how that variance can be reduced effectively is essential information for future development of boron and germanium containing niobium silicide-based alloys.

Macro-Micro segregation can usually be calculated from taking large area EDS analysis at the top, middle and bottom of the ingot. However, as boron is present, EPMA with wavelength dispersive spectroscopy (WDS) capabilities is required. WDS provides much better spectral resolution and allows trace analysis to be carried out. Large area quantitative elemental maps taken at specified regions of each alloy can be used to obtain the average macro-segregation wt.% values for each element.

Methods/materials

Elements of high purity were weighed out and vacuum arc melted together to form niobium silicide based ingots. The ingots were flipped 5 times and re-melted to improve homogeneity. Four alloys were made of compositions; Nb-24Ti-18Si-5Cr-5Al (KZ5), Nb-24Ti-18Si-5Cr-5Al-5Ge-5B (JW1), Nb-24Ti-18Si-5Cr-5Al-5Ge-10B (JW2), Nb-24Ti-18Si-5Cr-5Al-10Ge-5B (JW3). Samples were sectioned, mounted in conductive Bakelite and ground to a final polishing step of 50 nm diamond suspension. EPMA was carried out using a Jeol JXA 8350F instrument equipped with a field emission gun. Beam conditions used was 10KeV and 100nA in order to obtain sufficient counts and to ensure the excitation of Cr Ka x-rays. The WDS system was set up with a number of crystals depending on the element analysed. For example for boron a LDE2H crystal was used.

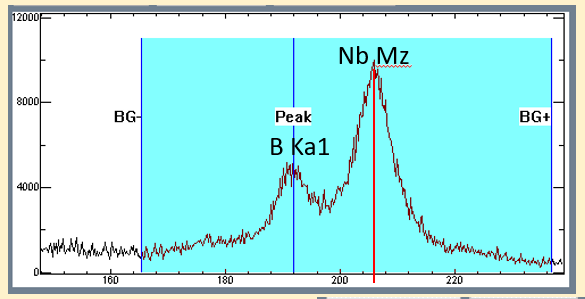

EPMA is associated using known reference standards for calibration, which takes into account peak interferences. One such challenge is the interference (peak overlap) effects between B Ka1 and Nb M2-Z peaks. (see attached figure 1). An interference correction factor was applied which accounted for the peak overlap; using the OEM PC-EPMA software supplied with the instrument. This provided much more accurate analysis data for boron for the phases identified within the alloy.

Fig 1: Peak Interference B- Ka1 and Nb-Mz peaks (LDE2H crystal on NbB standard).

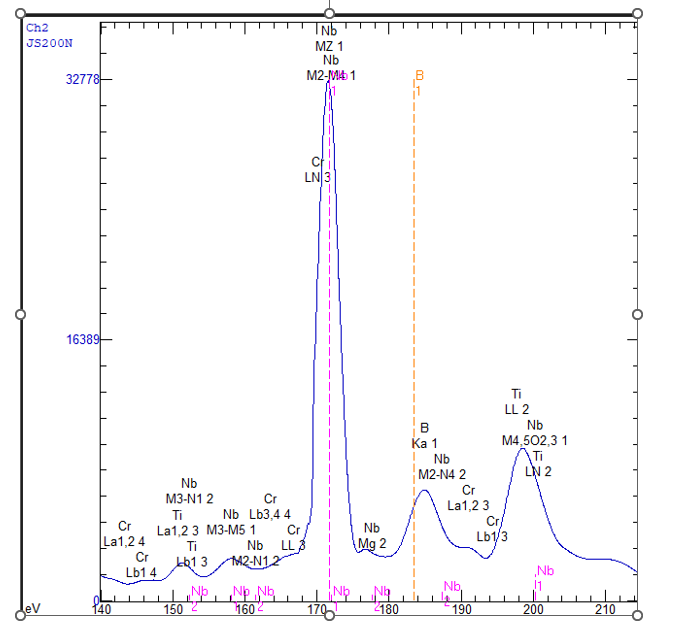

Addition scans were obtained using a soft x-ray emission spectrometer (SXES) with 5KV and 50nA beam conditions. Scans using this technique, while still exhibiting the peak interference effects, provided significantly enhanced spectral resolution across the peak energies under investigation. An SXES scan is shown in figure 2, illustrating the relationship between the B Ka1 and Nb-Mz peaks.

Figure 2: SXES scan of B Ka 1 in relation to peak interference with other alloying elements.

Results:

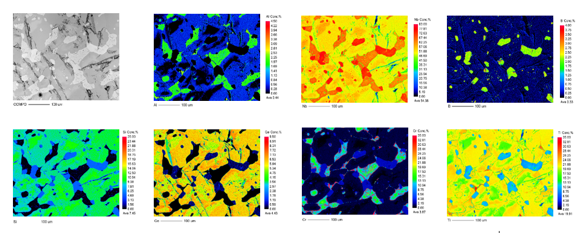

Preliminary findings have shown good results for quantification and showing the distribution of alloying elements including boron within each of the phases. This has been compared favourably with results obtained from another institution working on the same samples. WDS quantitative mapping has shown (see figure 3) clearly the elemental distribution for each phase and also an average composition over the entire map. Many maps were acquired to build up statistical data and to show compositional differences through the ingot.

Figure 3 WDS Compositional Maps of the Alloying Elements (includes BSE image).

The analysis work has now expanded to examine the phases and elemental compositions of the heat treated ingots and will progress to the other alloys in the series.

Conclusions

Using EPMA with WDS analysis has provided the spectral resolution and ability to undertake trace analysis of a range of elements including boron in the niobium silicide alloys. The calculation and using the interference correction factor has significantly increased the accuracy of boron analysis within each phase.

Accurate and reproducible analytical data has been obtained which characterise the distribution of elements within each phase. This has been confirmed by compositional maps.

The macro and micro segregation of elements and hence phases within the "as cast" and heat treated ingots have been profiled.

Boron, however is a difficult element to analyse due to problems with absorption and excitation (including peak shift) as the probe interacts with the varying element composition differences in each phase (matrix effects). The analysis would therefore benefit from further work including refinement of the mass absorption coefficients (mac). [3]

SXES offers the potential for enhanced spectral resolution of low energy emissions, corresponding data for a series of reference standards would enable the generation of specific calibration curves for further unknown material investigations. This is currently under development.

- References

[1] K. Zelenitsas, P. Tsakiropoulos; Intermetallics, 2005, 13, 1079-1095.

[2] L. Su, L. Jia, J. Weng, et al; Corros. Sci, 2014, 88, 460-465.

[3] G. F. Bastin, H.J.M. Heijligers; Quantitative Electron Probe Microanalysis of Boron, Carbon, Nitrogen and Oxygen. (ISBN 978-94-6228-222-3).