Metallography of organ pipe grain structure may enable more faithful conservation of historical musical instruments

- Abstract number

- 322

- Presentation Form

- Poster

- DOI

- 10.22443/rms.mmc2023.322

- Corresponding Email

- [email protected]

- Session

- Poster Session Three

- Authors

- Dr Yangchen Lin (1)

- Affiliations

-

1. Centre for Bioimaging Sciences, National University of Singapore

- Keywords

organ pipe

musical instrument

materials science

metallurgy

metallography

microscopy

polarized light

eutectic alloy

tin

lead

grain structure

microstructure

phase separation

- Abstract text

Pipe organs are significant culture heritage in Europe, and there is much activity by organ builders and conservationists to both restore centuries-old instruments to their original state or build new instruments faithful to traditional sound characteristics. Key to this is the manufacture of organ pipes, most of which are made of tin-lead alloys. Most efforts to replicate old pipes have only considered the composition of and impurities in the alloy. No one to my knowledge has examined the grain structure, which may affect the sound and should therefore be given attention. A sample of tin-lead alloy from an organ pipe made by notable manufacturer Klais was polished and etched for metallographic observation.

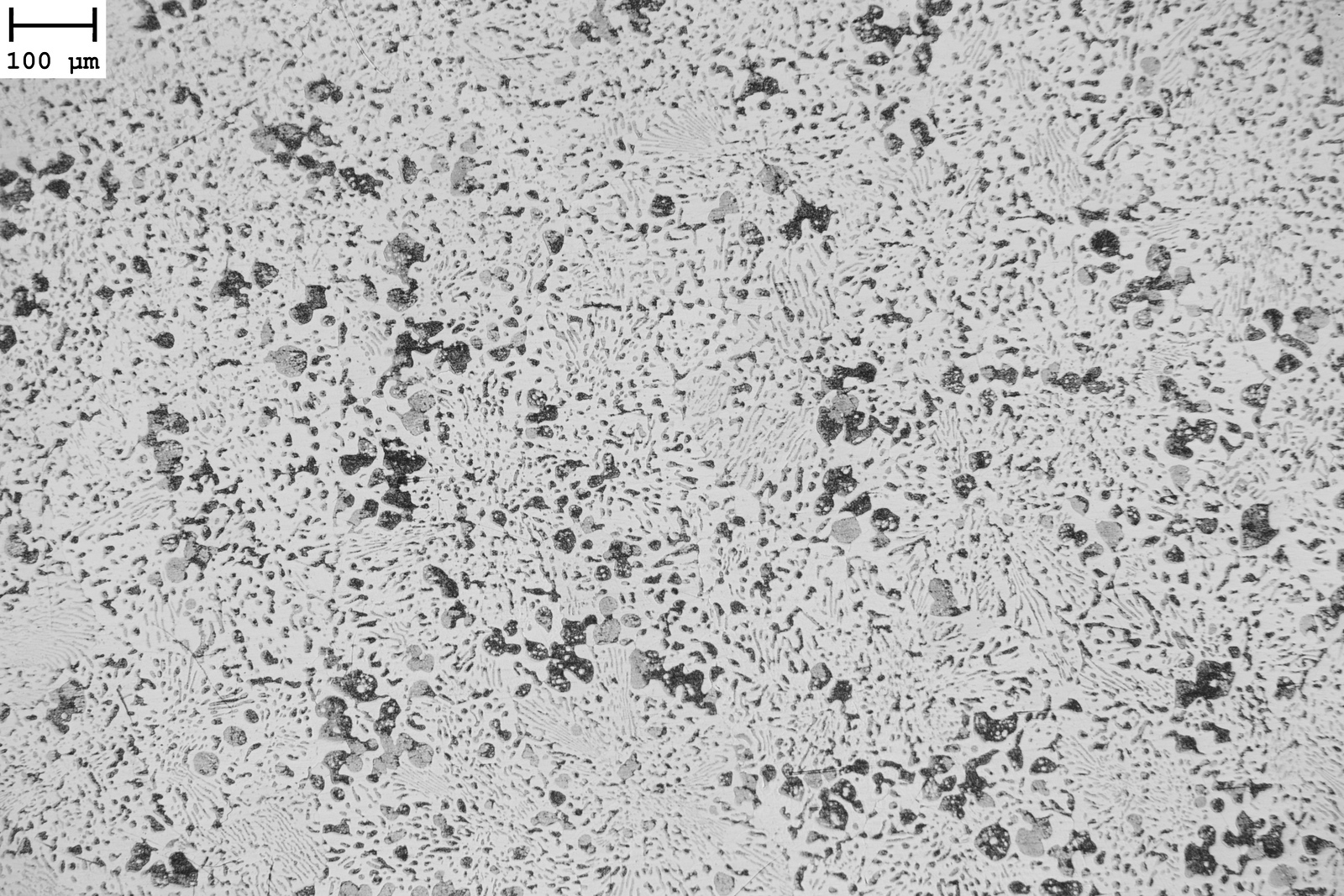

As expected, normal reflected bright-field illumination revealed the lamellar microstructures of the two eutectic phases that enable one to estimate alloy composition (above).

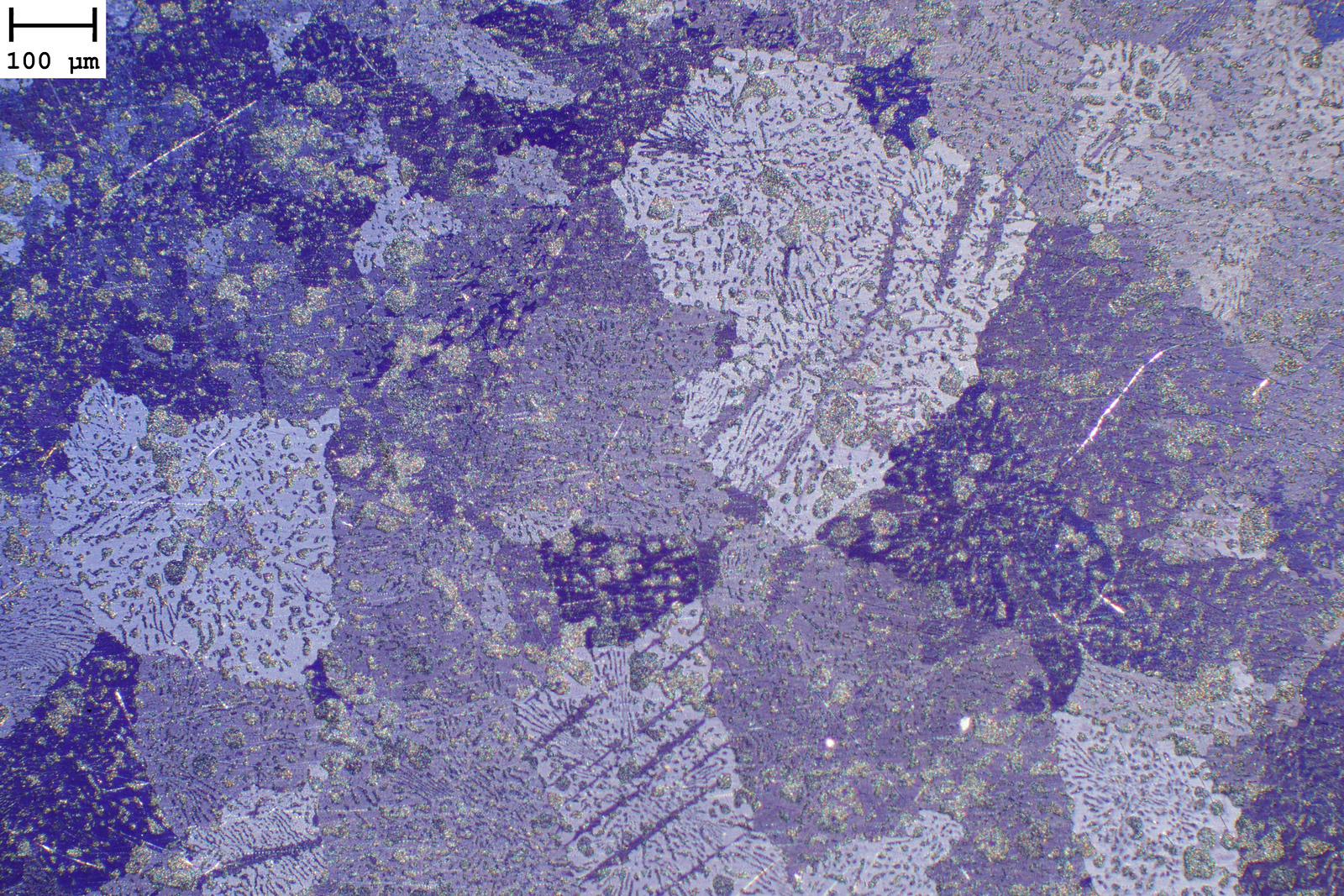

However, only when cross-polarized light was used did the larger-scale grain structure become visible (above). I will show and discuss micrographs comparing different-sized grain patterns as well as further computational analysis. The size and shape of the grains, which depend on factors such as the temperature of the molten pipe alloy and its rate of cooling, could enable organ conservationists to more faithfully emulate historical pipe-making methods.

- References

Detailed references will be given in the presentation.