Microstructural Based Life Assessment of 1CrMoV Turbine Rotors

- Abstract number

- 142

- Presentation Form

- Contributed Talk

- DOI

- 10.22443/rms.mmc2023.142

- Corresponding Email

- [email protected]

- Session

- EMAG - Functional Materials

- Authors

- Mr Hlanganani Nyembe (1), Dr Johan Westraadt (1)

- Affiliations

-

1. Nelson Mandela University

- Keywords

1CrMoV rotor, microstructure, creep, electron microscopy, remaining life assessment

- Abstract text

Creep-resistant 1CrMoV steels are used for high-pressure turbine rotors in fossil fuel power stations operated at steam temperatures up to 565 °C in the creep regime. The creep resistance of 1CrMoV steels is due to the dispersion of alloy carbides and solid solution strengthening by substitutional atoms. The carbide phases (size, population, and composition), solid solution alloy composition, bainitic laths, misorientations, dislocations, and cavities change (due to creep deformation) with the service time for 1CrMoV rotors operated at >510 °C [1,2,3]. However, for the service-exposed 1CrMoV rotors, the quantitative relationships between the microstructural evolution and remaining life are lacking. This study aimed to relate the microstructural changes for service-exposed 1CrMoV rotors to the creep life fraction as determined using existing methods.

Analytical electron microscopy was applied to study quantitatively the microstructural evolution of service-exposed 1CrMoV steel rotors. 1CrMoV rotor samples were characterised in the initial state, and three long-term (272 265 h to 300 409 h) service exposed states. Detailed microstructural investigations were conducted to analyse the cavities, bainitic laths and packets, dislocations, carbide phases and their size, population, and composition. The creep life fractions were estimated using conventional life assessment methods based on creep cavitation and hardness. The bainitic packets, laths, misorientations, and dislocations were analysed using electron backscattered diffraction (EBSD). The precipitates were extracted from the Fe-matrix using extraction replication and were studied further using transmission Kikuchi diffraction (TKD), scanning transmission electron microscopy (STEM), selected area electron diffraction (SAED), and energy dispersive X-ray spectroscopy (EDS). STEM, EDS, and SAED observations were performed using JEOL JEM 2100 equipped with an Oxford AZtec EDS system. EBSD, TKD and EDS characterisation was performed with JEOL SEM F7001 equipped with an Oxford AZtec EBSD and EDS system.

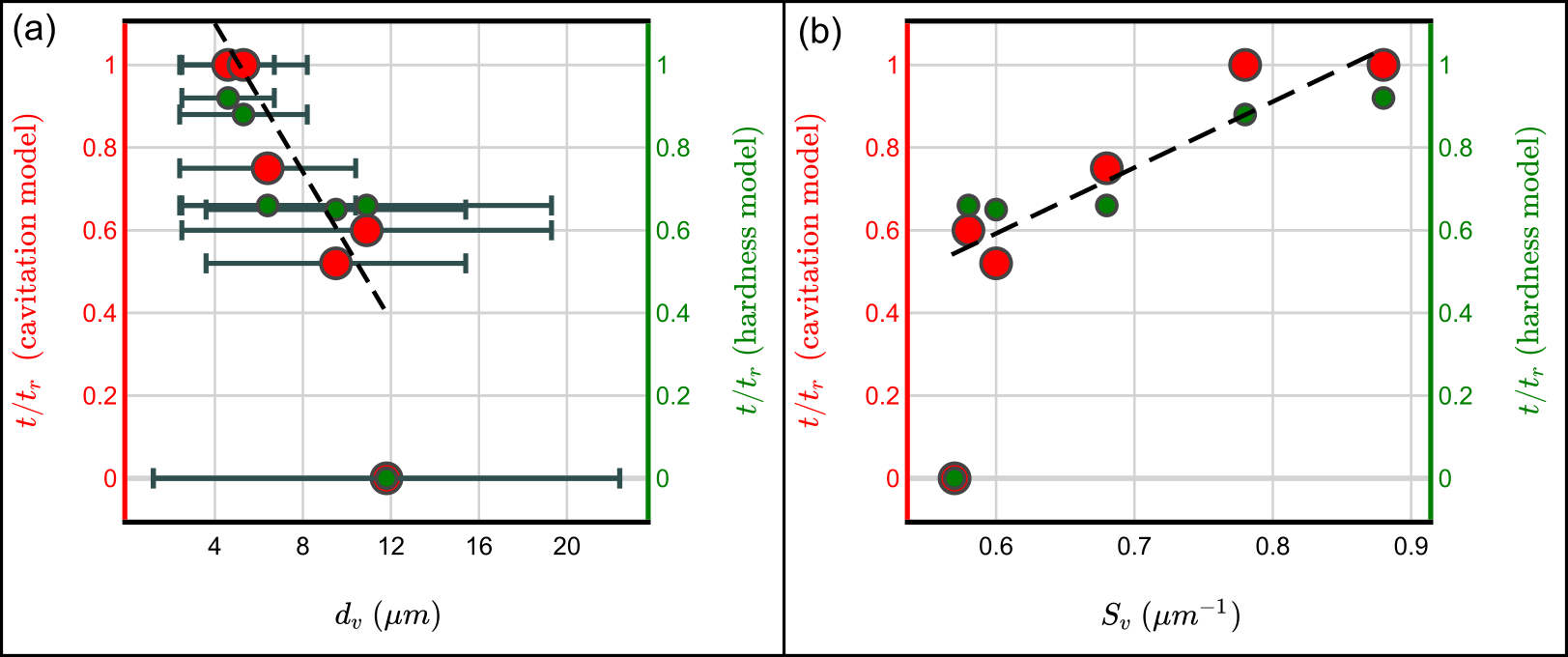

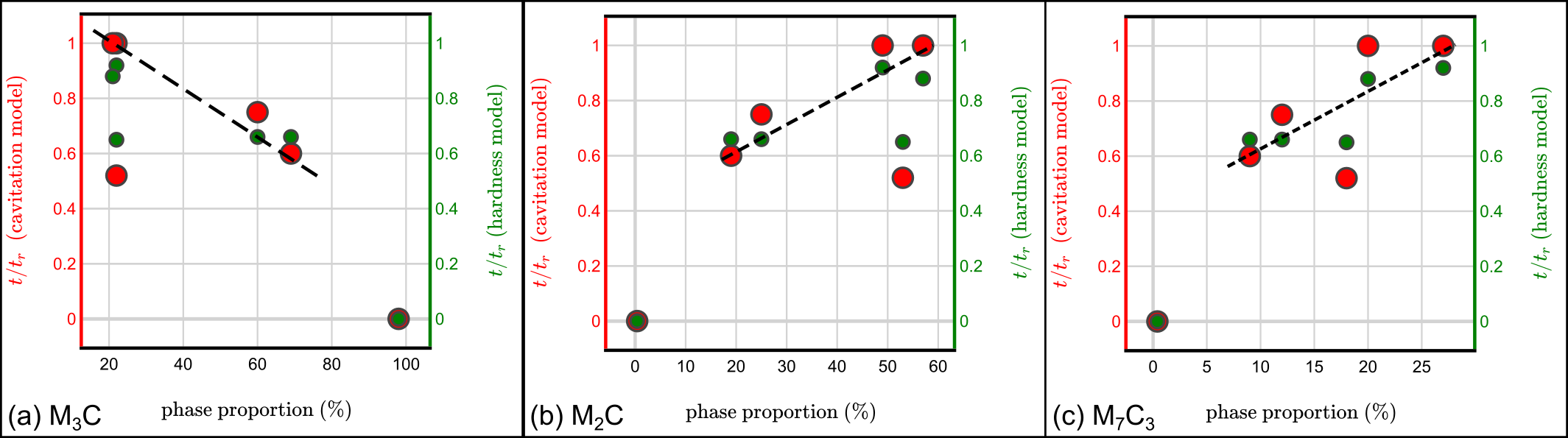

The creep life fraction (t/tr) of the rotors estimated based on the creep cavities (CM) and hardness (HM) data are summarised in Table 1. EBSD showed that the average size (dV) and surface-to-volume ratio (SV) of bainitic laths correlated with creep life fraction as shown in Fig. 1 (a) and (b), respectively. STEM-EDS, SAED, and TKD identified M3C, MC, M2C, M7C3, and M23C6 carbides (M = Fe, Cr, Mo, V, Mn) in 1CrMoV rotors. STEM-EDS measurements revealed that Fe/Cr ratios in M3C decreased from 4.5 (t/tr = 0) to 2.5 (t/tr > 0.5). The Fe/Cr and Fe/Mo ratios in overall carbides were 5 and 10 at t/tr = 0 and decreased to 1 and 2 at t/tr > 0.5, respectively. TKD analysis of precipitates revealed the phase proportion of M3C, M2C, and M7C3 carbides in service-exposed 1CrMoV rotors vary with creep life fraction as shown in Fig. 2 (a), (b), and (c), respectively. The observed quantitative relationship between the microstructural features and creep life fraction of service-exposed 1CrMoV rotors might be used as another indicator of the remaining life.

Table 1. Life fraction of the rotors estimated with cavitation (CM) and hardness (HM) models.

Rotor 1 (s 1) 1 (s 2) 2 3 4 t/tr CM 0.75 0.6 >1 >1 0.52 HM 0.66 0.66 0.92 0.88 0.65 Figure 1. The variation of (a) average lath size and (b) lath surface density with the estimated creep life fraction of the rotors.

Figure 2. The variation of phase proportions for (a) M3C, (b) M2C, and M7C3 carbides with the estimated creep life fraction of the rotors.

The characteristics of bainitic laths and misorientations were effectively evaluated using the EBSD on a statistically significant basis. TKD-EDS analysis on extraction replicas was successfully used on the 1CrMoV steels to analyse a statistically representative number of precipitates using the SEM. Generally, precipitate, lath, and lath-lath misorientation analyses are accomplished using time-consuming TEM based techniques because of the spatial resolution limits of SEM analysis of bulk samples.

This study showed that advanced electron microscopy microstructural characterisation techniques could find relationships between the microstructural evolution and creep life of 1CrMoV steel rotors. In addition, these characterisation methods can apply to other low alloy steel power plant components. However, variations in the initial material state (composition, heat treatments), which could influence the subsequent microstructural evolution, need to be considered when building microstructural-based remaining life assessment models. The future work will include a dictionary indexing approach for EBSD/TKD to improve the indexing rate, which will consequently lessen the uncertainties in the microstructure measurements.

- References

- Mitchell, D.R.G. and C.J. Moss, Characterization of seven power-generating turbine rotors using microscopy-based techniques. Journal of materials engineering and performance, 1998. 7(5): p. 621–631.

- Joarder, A., D.S. Sarma, and N.S. Cheruvu, Effect of long-term service exposure on microstructure and mechanical properties of a CrMoV steam turbine rotor steel. Metallurgical Transactions A, 1991. 22(8): p. 1811–1820.

- van der Meer, P., et al., Effect of geometry on the microstructural ageing of a 1CrMoNiV turbine rotor steel, in International ECCC conference. 2014.