PLASTIC DEFORMATION OF NANOSCALE MATERIALS - IN SITU TEM AND MOLECULAR DYNAMICS STUDY

- Abstract number

- 350

- Presentation Form

- Contributed Talk

- Corresponding Email

- [email protected]

- Session

- EMAG - EM Data Processing & Analysis

- Authors

- Lucia Bajtošová (1), Barbora Kihoulou (1), Rostislav Králík (1), Jan Hanuš (1), Petr Harcuba (1), Jan Fikar (2), Ankit Yadav (2), Miroslav Cieslar (1)

- Affiliations

-

1. Charles University

2. Czech Academy of Sciences

- Keywords

nanocrystalline films, tensile deformation, in situ TEM, molecular dynamics

- Abstract text

The study is focused on the deformation of nanocrystalline thin films, which are deformed in situ in TEM, and the results are compared to the molecular dynamics simulations. Main deformation mechanisms in Al and Fe-based films are investigated.

The applicability of thin films is connected chiefly to micro-electro-mechanical systems, in which they undergo mechanical straining. In nanoscale films, mechanical properties are linked to their dimensions, small grain sizes, and film thickness leading to the activation of deformation mechanisms different from the bulk materials [1]. In situ transmission electron microscopy [2] allows both direct observation of the ongoing mechanisms in the sample and the measurement of mechanical properties. Combined with molecular dynamics (MD) simulations [3], determining mechanisms on the atomic level can be achieved.

Films between 50 and 150 nm thick were prepared by a DC magnetron sputtering from Al3%wt. Mg alloy and DC01 steel. Free-standing films were prepared by dissolving the substrate. They were then annealed in situ to allow grain growth and reduce the internal stresses. The dog-bone shape specimen was cut from the film in a scanning electron microscope Zeiss Auriga using a focused ion beam, fixed onto a Hysitron Push-to-Pull device, and deformed by Hysitron PI 95 TEM PicoIndenter. The nanocrystalline structure for the simulations was constructed using Atomsk software [4]. Hexagonal columnar grains were created in the box with periodic boundary conditions employed in the x and y directions. The MD simulations were performed using a Large-Scale Atomic/Molecular Massively Parallel Simulator (LAMMPS) [5].

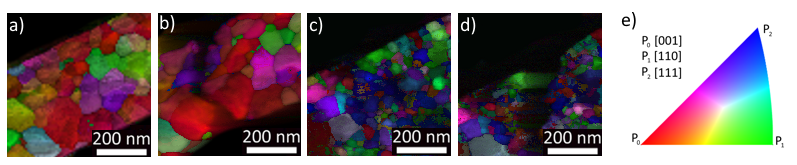

In Al-based films, inverse Hall Petch behavior was detected. ASTAR orientation maps before and after the failure were used to determine grain rotations as the primary deformation mechanism (Figure 1). Misorientation changes between individual grains 0.5º - 2º large were detected. Moreover, the intergranular character of the crack propagation can be deduced from ASTAR images taken after the failure. On the contrary, mostly inside grain dislocation motion was observed in the Fe-based films, with normal Hall Petch behavior and intragranular failure.

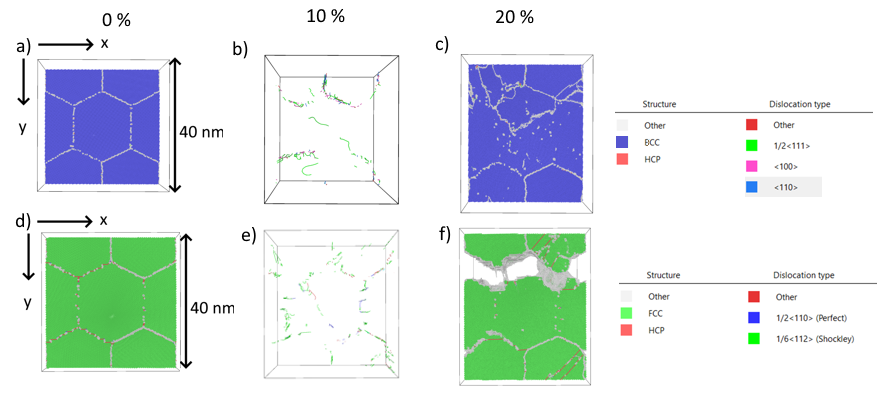

The simulation results matched some of the main features observed in the experiment. Namely, the extent of dislocation motion and the character of the failure were compliant for both materials. However, measurements of grain rotations via polyhedral template matching [6] showed no significant changes between misorientations at the beginning and end of the simulation. The young modulus values in simulations approach theoretical bulk values and are much larger than the measured experimental ones. Visualization of simulation results is shown in Fig. 2.

In conclusion, different deformation mechanisms were detected in nanocrystalline Al- and Fe-based thin films. Al-based films were deformed by grain boundary-related mechanisms, while in Fe-based films, intergranular dislocation motion prevailed. MD simulations with simplified hexagonal grains correctly reproduce some of the main features of the deformation processes observed in in-situ TEM.

Fig. 1: ASTAR images of the films before (a,c) and after (b,d) deformation, a,b) Al-based film, c,d) Fe-based film.

Fig. 2: Visualization of MD simulation results, a,d) 0%, b,e) 10%, c,f) 20%, a,c,d,f) common neighbor analysis, b,e) dislocation analysis, a-c) Al film, d-f) Fe film.

- References

[1] Uchic M D 2004 Science. 305 986-989.

[2] Kumar K S 2003 Acta Mater. 51 387-405.

[3] Abraham F F 1986 Adv. Phys. 35 1-111.

[4] Hirel P 2015 J Comput. Phys. Commun. 197 212-219.

[5] Plimpton J 1995 J Comp Phys 117 1-19.

[6] Xu D, Tian Y 2015 Ann. Data Sci. 2015 165-193.