Scanning precession electron diffraction for structural analysis of polycrystalline ferroelectrics

- Abstract number

- 387

- Presentation Form

- Contributed Talk

- DOI

- 10.22443/rms.mmc2023.387

- Corresponding Email

- [email protected]

- Session

- EMAG - High Resolution Structural Analysis

- Authors

- A. C. Mathisen (2), L. M. Côrrea (3), K. A. Hunnestad (1), J. Schultheiß (1, 4), E. F. Christiansen (2), D. Meier (1), D. Ugarte (3), A. T. J. van Helvoort (2)

- Affiliations

-

1. Department of Materials Science and Engineering, Norwegian University of Science and Technology (NTNU)

2. Department of Physics, Norwegian University of Science and Technology (NTNU)

3. Instituto de Fisica “Gleb Wataghin”, Universidade Estadual de Campinas (UNICAMP)

4. Experimental Physics V, University of Augsburg

- Keywords

Ferroeelectrics, ErMnO3, precession, diffraction, open-source

- Abstract text

In this contribution we will demonstrate that through scanning precession electron diffraction (SPED), detailed structural information can be extracted regarding crystal orientation over relatively large areas. This will be demonstrated for a ferroelectric h-ErMnO3 polycrystal [1]. We will discuss how intensities in the diffraction patterns can be used to refine the structural analysis, increasing orientation precision and crystal description with the aim of mapping ferroelectric domains, even for grains in off-zone-axis crystal orientations.

For this work, a commercial scanning precession set-up on a standard 200 kV field emission transmission electron microscope along with a focus ion beam prepared lamella specimen are used. Our results will demonstrate the importance of precession of the electron beam and data collection using a direct electron detector. In the present work, the precession angle is limited to 1˚ to preserve sufficient spatial resolution. All analysis is done in open-source software, primarily the phyton library pyXem [2,3] and a home-made software for diffracted intensity analysis [3].

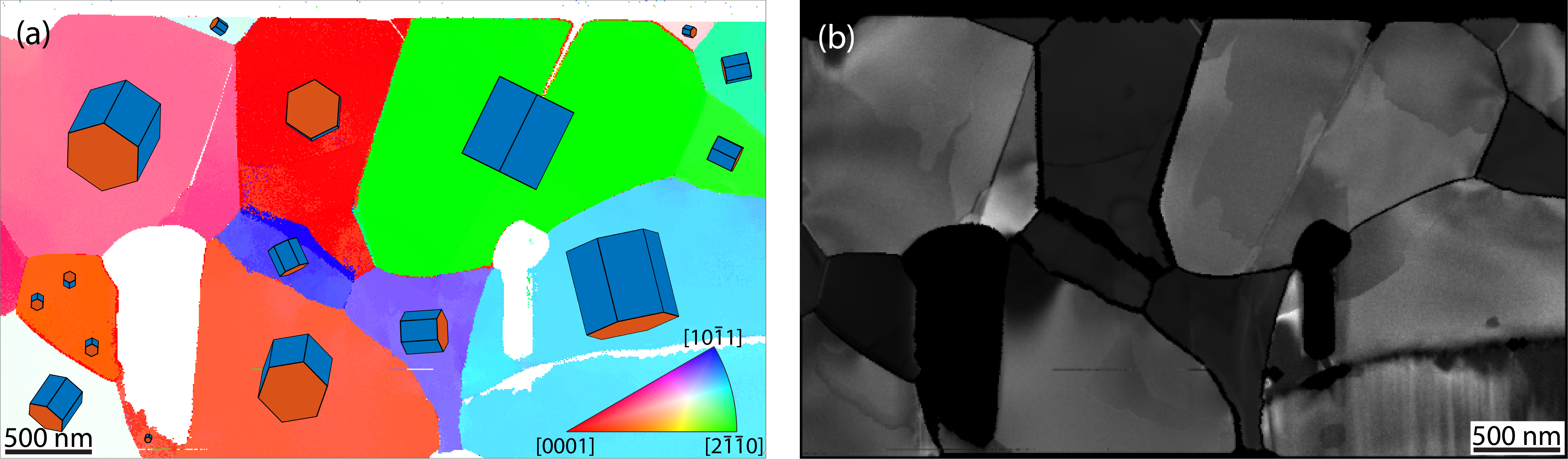

After pre-prossessing the stack of diffraction patterns, such as aligning the frames and background subtraction, an orientation map can be constructed using template matching where each experimental pattern is compared to a library of kinematically simulated patterns [4]. The ranking of the solutions is based on a normalized cross correlation. Figure 1(a) depicts the resulting orientation map with a model unit cell depicting the crystal orientation. We estimate the angular resolution of template orientation matching routine just below 1˚. The matching results can be used to calculate the component of the polar c-axis within the lamella plane. Furthermore, the angle between c-axis of adjacent grains and thereby the induced charging of a grain boundary due to the ferroelectric polarization in grains can be estimated.

Figure 1: (a) Orientation map (in beam direction) with model unit cells plotted on top of each grain. (b) Ensemble of manually constructed virtual dark-field images which depicts clear domain contrast for some grains.

By capturing the SPED data at higher camera lengths, the strain and the polarization can potentially be analyzed [5]. However, in default template matching, and strain and field analysis, the information contained in the intensity variations of diffraction reflections is often disregarded. Using this valuable parameter can improve the structure analysis. For example, to deduce the polarization direction in the non-centrosymmetric structure, dynamical intensity variations between g and -g reflection pairs with a component along the polarization direction (c-axis) must be considered. Constructing virtual dark-fields from different grains reveals that domain specific intensity variations are present in the precession data (Fig.1(b)). In comparison, non-precessed beam data and conventional dark-field transmission electron microscopy have a weaker domain contrast, as dynamical intensity variations due to small orientation, thickness and strain variations across the grain can dominate overall contrast.

We will propose an analytical two-beam dynamic diffraction model to perform a quantitative analysis of diffraction intensities and refine the structural analysis with crystal orientation and specimen thickness as parameters [3]. In the present case, the aim is to deduce, beside the grain orientations, the polarization direction within a domain. Furthermore, the orientation and strain analysis might be improved compared to the initial analysis primarily based on the (relative) reflection positions. We will discuss why this quantitative refinement of crystal characteristics based on diffraction intensities can be applied for precession electron diffraction data. For ferroelectric materials simultaneous and accurate understanding of crystal orientation, strain and polarization is important. Moreover, scanning electron diffraction as preformed here has advantages compared to atomically resolved high-angle annular dark-field scanning transmission electron microscopy, routinely used for ferroelectrics. These advantages include a larger field-of-view, analyzing in off-zone orientations and significantly lowering the electron dose and are particularly beneficial in measuring structural details of polycrystalline ferroelectric materials.

- References

[1] Schultheiß, J., Xue, F., Roede, E., Ånes, H. W., Danmo, F. H., Selbach, S. M., Chen, L.-Q., Meier, D., Confinement-Driven Inverse Domain Scaling in Polycrystalline ErMnO3. Adv. Mater., 34, 2203449, 2022. https://doi.org/10.1002/adma.202203449

[2] pyxem, DOI 10.5281/zenodo.2649351.

[3] Corrêa L., Ortega, E., Ponce A., Cotta M., Ugarte D. M., arXiv, 2023, https://doi.org/10.48550/arxiv.2301.10286.

[4] Cautaerts N., Crout P., Ånes H., Prestat E., Jeong J., Dehm G., Liebscher C. H., Ultramicroscopy, 237, 113517, 2022. Doi: 10.1016/j.ultramic.2022.113517

[5] Ophus C., Microscopy and Microanalysis, 25(3), 563-582, 2019. doi:10.1017/S1431927619000497

[6] Acknowledgements: NRF for support for NORTEM-facility (197405). LMC and DU thank support from CNPq, CAPES and FAPESP and DM acknowledges funding from the European Research Council (ERC) under the European Union’s Horizon 2020 research and innovation program (Grant Agreement No. 863691).