Scanning transmission electron microscopy and in situ heating reveal the development of individual nanoscale precipitates in an Al-Mg-Si-Cu alloy

- Abstract number

- 168

- Presentation Form

- Contributed Talk

- DOI

- 10.22443/rms.mmc2023.168

- Corresponding Email

- [email protected]

- Session

- EMAG - High Resolution Structural Analysis

- Authors

- Tina Bergh (1), Elisabeth Thronsen (4), Jørgen A. Sørhaug (2), Kristin Frøystein (2), Jonas K. Sunde (3), Per Erik Vullum (4, 2), Randi Holmestad (2)

- Affiliations

-

1. Department of Chemical Engineering, Norwegian University of Science and Technology (NTNU)

2. Department of Physics, Norwegian University of Science and Technology (NTNU)

3. Norsk Hydro ASA, Innovation & Technology - Precision Tubing

4. SINTEF Industry, Materials and Nanotechnology

- Keywords

in situ heating, scanning transmission electron microscopy, scanning precession electron diffraction, aluminium, precipitates, Al-Mg-Si-Cu

- Abstract text

Nanoscale precipitates provide the main contribution to strengthening in age-hardenable aluminium alloys. Thermomechanical treatment and chemical composition decide how the precipitates form and develop. For 6xxx Al-Mg-Si alloys, the main hardening phase is the β’’-Mg-Si phase which grows as needles along the <001> Al directions. If Cu is added to an Al-Mg-Si alloy, the precipitate evolution changes, and also the more thermally stable L [1] and the Q’ precipitate phases appear during ageing. Characterisation of these precipitates is crucial for understanding how the precipitate types and size distributions can be tailored to optimise the alloy properties. (Scanning) transmission electron microscopy ((S)TEM) techniques enable describing these nanoscale precipitates in terms of morphology, number density, chemical composition, and crystal structure, all of which greatly affect the alloy properties. By combining (S)TEM and in situ heating, it is possible to follow the growth, transformation, and subsequent dissolution of individual precipitates [2], and thereby directly study the precipitation sequence of the alloy.

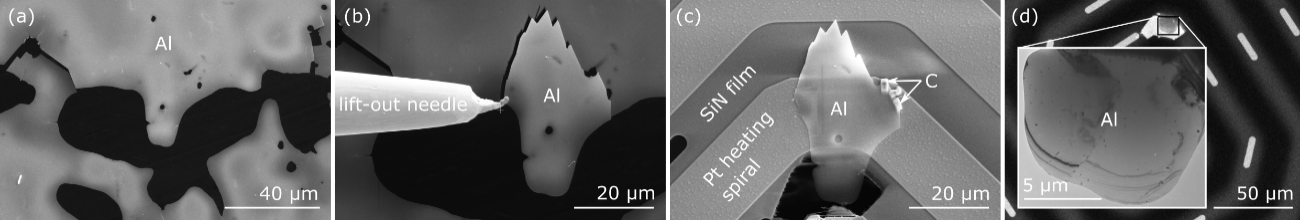

In this work, in situ heating of an Al-0.86Mg-0.62Si-0.10Cu (at.%) alloy was performed with the goal of following the evolution of individual precipitates. The specimen was prepared by first following the standard approach of mechanical grinding and electropolishing. Then, TEM was used to locate a thin region suitably oriented close to the <001> Al zone axis. The selected region was transferred to a heating chip by focused ion-beam (FIB) lift-out, as shown in Figure 1. High angle annular dark-field STEM performed in an aberration corrected JEOL ARM200 microscope was used to identify the precipitate phases present prior to in situ heat treatment. The specimen was heated from room temperature and up to 520oC at a rate of 0.01 K/s using a DENSsolutions wildfire holder in a JEOL JEM 2100F microscope.

Figure 1: Specimen preparation. SEM images showing (a) electropolished Al, (b) after FIB has been used to cut out a large Al piece attached to a lift-out needle, and (c) after the Al region has been fastened to a heating chip using C deposition. (d) Bright-field (BF) TEM image of the thin region of interest.

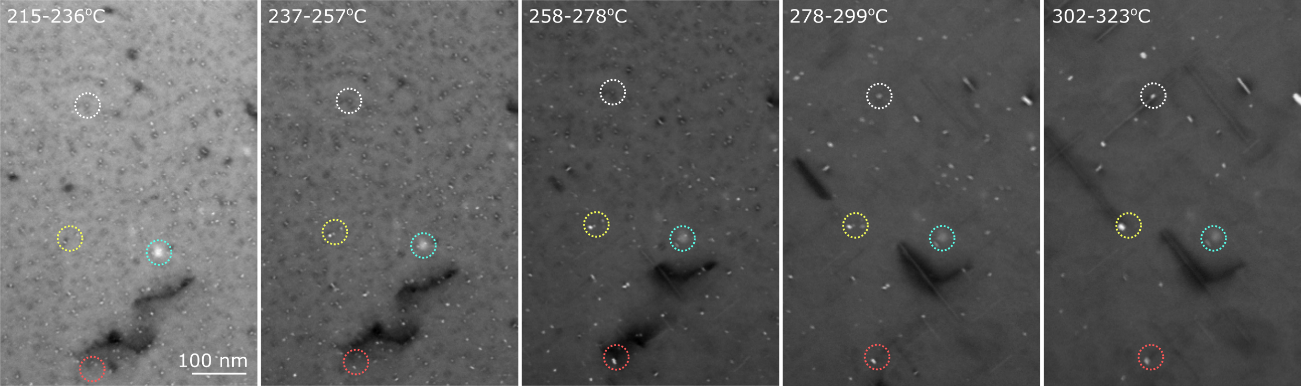

During in situ heating, scanning precession electron diffraction (SPED) was performed to characterise the precipitates based on their crystal structures. SPED involves scanning a nanometre-sized electron probe while precessing the beam and collecting a PED pattern for each probe position. The four-dimensional datasets were acquired on a Medipix direct electron detector using a Quantum Detectors Merlin system. Figure 2 shows virtual annular dark-field images from selected SPED scans, where the reduction in number density and growth of precipitates can be seen. Each SPED dataset was analysed using non-negative matrix factorisation combined with image thresholding to produce precipitate phase maps providing good statistics on the relative phase occurrences [3]. The growth and subsequent dissolution of individual β’’, L, β’ and Q’ precipitates were revealed as a function of temperature. The thickness of the mapped specimen region was determined using convergent beam electron diffraction, and the effect of specimen thickness on the in situ precipitate evolution is discussed. In total, this work provides insights both in terms of the precipitate evolution in the Al-Mg-Si-Cu alloy and the methodology for (S)TEM in situ heating.

Figure 2: Virtual annular dark-field images created from selected SPED scans collected during in situ heating. The coloured circles mark corresponding areas.

- References

The authors acknowledge the support from the Research Council of Norway to the projects: iCSI (237922), AluBridge (314063), in-sane (301176), SFI Manufacturing (237900), NORTEM (197405) and NorFab (295864).

[1] C.D. Marioara et al. «Improving Thermal Stability in Cu-Containing Al-Mg-Si Alloys by Precipitate Optimization». (2014) Metallurgical and Materials Transactions A 45, 2938–2949. https://doi.org/10.1007/s11661-014-2250-0

[2] J.K. Sunde, S. Wenner & R. Holmestad, «In situ heating TEM observations of evolving nanoscale Al–Mg–Si–Cu precipitates”. (2020) Journal of Microscopy 279, 143. https://doi.org/10.1111/jmi.12845

[3] J.K. Sunde et al. “The evolution of precipitate crystal structures in an Al-Mg-Si(-Cu) alloy studied by a combined HAADF-STEM and SPED approach”. (2018) Materials Characterization 142, 458, https://doi.org/10.1016/j.matchar.2018.05.031