Strain mapping in 3D printed 304L austenitic steel using scanning precession electron diffraction

- Abstract number

- 366

- Presentation Form

- Contributed Talk

- Corresponding Email

- [email protected]

- Session

- EMAG - EM Data Processing & Analysis

- Authors

- Petr Vacek (1), Vít Horník (2), Michal Jambor (2), Miroslav Šmíd (2), Paul Midgley (1)

- Affiliations

-

1. Department of Materials Science and Metallurgy, University of Cambridge

2. Institute of Physics of Materials, Czech Academy of Sciences

- Keywords

4D-STEM, Scanning precession electron diffraction, 3D Printing, Additive manufacturing, AISI 304L steel, Strain

- Abstract text

Additive manufacturing or 3D printing is an emerging technology where the object is manufactured layer by layer directly from a digital model. This approach offers significant freedom in designing components while maintaining high manufacturing precision. However, the microstructure of 3D printed materials is highly influenced by the high cooling rates during solidification of the molten layer during the printing process. This results in a cellular microstructure with elongated columnar grains [1]. In general, the rapid cooling also induces strain in the microstructure of the “as-built” state, and is an important factor in the understanding of the structural properties of 3D printed materials.

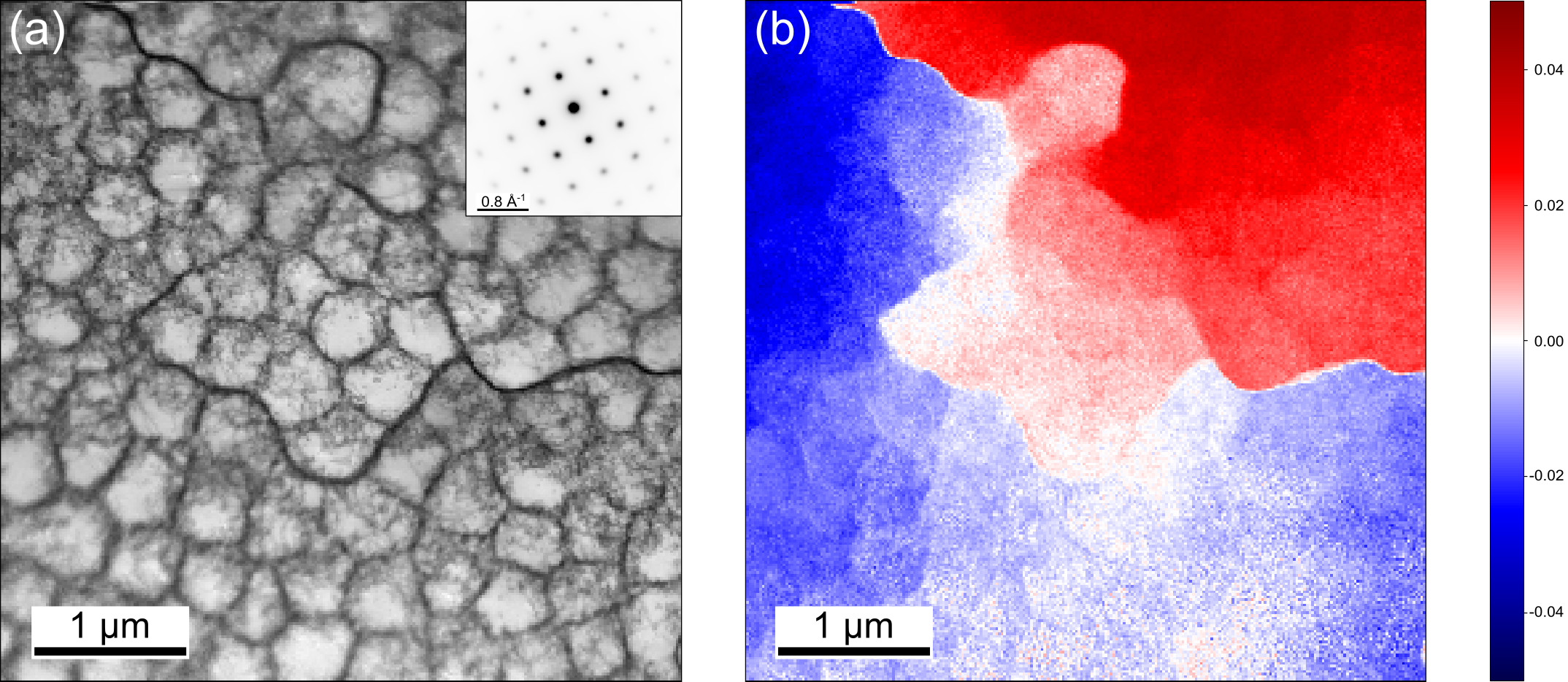

We present results of strain mapping on AISI 304L austenitic steel in the as-built state manufactured by selective laser melting. The microstructure of this steel shows a typical cellular structure. Cells ca. 400 nm in diameter are present inside of grains and are separated by an extensive dislocation network. The virtual bright field image (Figure 1, a) shows two types of boundaries between the cells, a darker and lighter one. These correspond to a sub-grain boundary and a cell boundary, respectively, each facilitated by a dislocation network. Scanning precession electron diffraction [2] was used to map changes in the strain and lattice rotation between individual cells and sub-grain boundaries. There is a sudden change in the lattice rotation at the sub-grain boundaries (ca. 3°), while cell boundaries have only a small misorientation with respect to surrounding cells; changes in lattice rotation are accommodated by the dislocation network. Strain mapping shows the largest variation in strain state mostly between the sub-grains. There are also subtle changes in the strain in the vicinity of the dislocation network and near the individual defects inside of the cells. The dislocation network separating individual cells plays an important role in deciding the overall strain distribution and lattice rotation in the microstructure of 3D printed 304L steel.

P Vacek, and P Midgley thank the EPSRC for funding under grant number EP/V007785/1, EP/R008779/1, and the European Union Horizon 2020 research and innovation programme (ESTEEM3): 823717. V Hornik, M Jambor, and M Smid are grateful for the financial support of the Czech Science Foundation by the project 23-07235S.

Figure 1: Virtual annular dark field image (a) and a lattice rotation image (b) of the cellular microstructure. Data recorded at 300 kV.

- References

[1] D. Kong, C. Dong, S. Wei, X. Ni, L. Zhang, R. Li, L. Wang, C. Man, X. Li, About metastable cellular structure in additively manufactured austenitic stainless steels, Addit Manuf. 38 (2021) 101804. https://doi.org/10.1016/j.addma.2020.101804.

[2] P.A. Midgley, A.S. Eggeman, Precession electron diffraction – a topical review, IUCrJ. 2 (2015) 126–136. https://doi.org/10.1107/S2052252514022283.