A correlative through the length scale study combining XRM-FIB-TEM instrumentation with machine learning to understand autocatalysts.

- Abstract number

- 161

- Presentation Form

- Poster

- DOI

- 10.22443/rms.mmc2021.161

- Corresponding Email

- [email protected]

- Session

- Poster Session 4

- Authors

- Dr Aakash Varambhia (1), Dr Angela Goode (1), Dr Gareth Hatton (1), Dr Trung Tran (1), Dr Markus Boese (2), Dr Dogan Ozkaya (1)

- Affiliations

-

1. Johnson Matthey

2. Zeiss

- Keywords

microscopy catalysts correlative XRM FIB SEM

- Abstract text

Autocatalysts have been around since the 1970’s and are one of the most effective ways to reduce smog and related pollution from car exhausts [1]. As a direct result of this reduction, most cities are cleaner places to live. The auto catalyst does this by reducing vehicle exhaust outputs such as carbon monoxide, nitrous oxides, and the soot to legislated levels. In this study we focus on a research grade Gasoline Particulate Filter (GPF).

The performance of the GPF is determined by three aspects that are in the macro, meso and atomic scale. At the macro scale, transport of the gas through the channels and interconnecting pores plays a role in determining catalytic active sites. At the meso scale the morphology of the catalyst nanoparticles and the micro-pore structure ensure that there are enough active sites accessible for the desired performance to reduce pollution. At the atomic scale, structural information of the catalyst material determines the performance and selectivity of the catalyst used within the GPF.

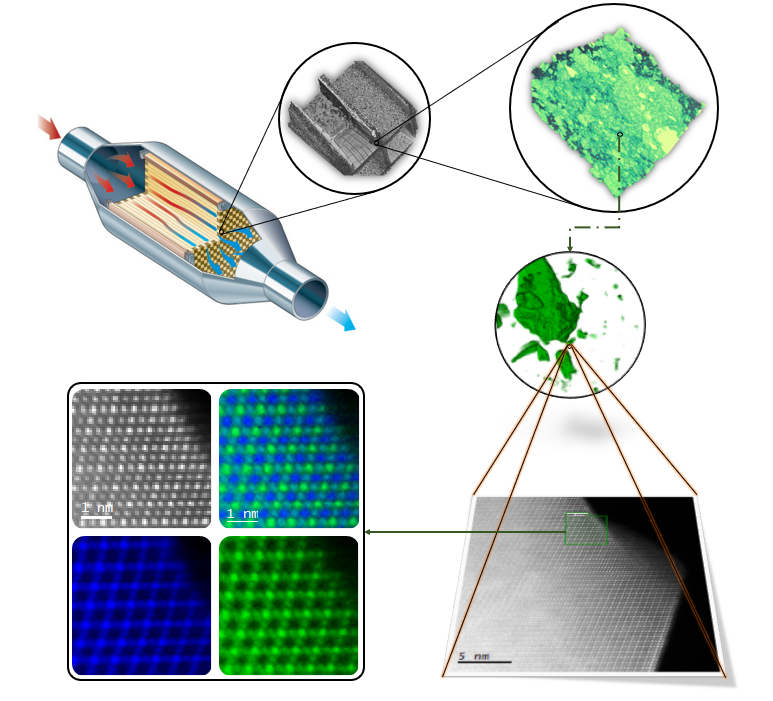

To investigate the GPF across its length in a correlative manner we required X-ray Microscopy (XRM), Focused Ion Beam Scanning Electron Microscopy (FIB-SEM) and Transmission Electron Microscopy (TEM), Figure 1. The strength of the XRM lies in observing the GPF’s properties at the macro-scale. Properties such as coating uniformity, location and pore network distribution can be determined with this technique. The strength of the FIB-SEM lies in observing the smaller features within the catalyst coating (also known as washcoat) [2], which are often missed by the resolution limit (~0.5µm) [2] of the XRM. The strength of the TEM lies in observing the atomic structure of the catalyst coupled with simultaneous spectroscopic information with chemical and oxidation state mapping.

Often when trying to correlate performance to rational catalyst design, several observations, measurements, and iterative refinement are necessary. Moreover, in industry, this must be done rapidly due to high turnover. This agile approach requires fast characterisation of materials in a corelative way. We present results and propose a workflow on how this can be achieved using a methodology aided by machine learning and automation combined with correlative experimentation.

In this presentation we show how a sample can be decomposed at the macro and meso scale into components using the Zeiss ZEN Intellesis machine learning segmentation software in combination with the Zeiss Atlas software [3] to correlate the length scales. Once both the macro and meso length scales are aligned, the sample was prepared using a Zeiss crossbeam 550 [4] for atomic resolution TEM imaging. Outputs from such a workflow can then translated to create a “digital twin” for a given sample to improve GPF design.

Figure 1. A through the length scale characterisation of a GPF spanning the macro, meso and atomic scale.

- References

[1] Twigg. M. Twenty-Five Years of Autocatalysts. Platinum Metals Rev., 43, (4), 168-171 (1999)

[2] Varambhia. A. et al. Correlative XRM-FIB/SEM Study of Autocatalysts, ZEISS whitepaper (2020) https://www.zeiss.com/microscopy/int/cmp/mat/20/soft-materials/wp-autocatalysts.html

[3] https://www.zeiss.com/microscopy/int/products/microscope-software/atlas.html