Design and in situ Environmental TEM characterization of a stable and robust self-assembled network of bi-metallic (Au-Pd) nanoparticles for CO oxidation

- Abstract number

- 271

- Presentation Form

- Poster

- Corresponding Email

- [email protected]

- Session

- Poster Session 4

- Authors

- Prof. Thierry Epicier (2), Ass.Prof. Eric Ehret (2), Prof. Bruno Domenichini (1), Mrs Laurence Burel (2), Dr Francisco-José Cadete Santos Aires (2, 3)

- Affiliations

-

1. ICB, Université de Bourgogne-CNRS

2. IRCELYON, Univ Lyon-UCBL-CNRS

3. Laboratory of Catalytic Research, National Research Tomsk State University

- Keywords

Environmental TEM; nanocatalysts; (Au,Pd) nanoparticles; inverse micelles; self-assembled network; in situ TEM; oxygen treatment; beam-induced irradiation effects

- Abstract text

Temperature-induced sintering occurs in most heterogenous catalysis reactions. This can be monitored to obtain catalytic particles with optimal sizes especially at low temperatures (for instance in CO oxidation). However, during catalytic high temperature reactions beyond 300°C, heterogeneous nanocatalysts are inevitably subjected to stronger sintering that may irreversibly result in the loss of catalytic activity and/or selectivity. Strategies for the design and rational fabrication of sinter-resistant catalysts have been developed. Among these, block-copolymer inverse micelle-based methods where metallic precursors are encapsulated in the micellar cores are attractive methods to prepare highly efficient and extraordinarily stable metal‐nanoparticle‐based catalysts. We used PS-P2VP block-copolymer micelles that were functionalized with precursors chloro-auric acid and palladium di-acetate. The precursors selectively bind with N-functions in P2VP to form (bi-)metallic seeds within the micelles’ cores as it was previously established in the case of PdAg alloys [1]. A molecular-thick layer of the solution was then deposited on a Wildfire SiNx heating nano-chip (DENSsolutions) by spin coating at 2000 rpm.

The native state of both polymeric filaments linking metallic aggregates within the cores, as well as the evolution of the latter was quantified in situ under reactive gas and temperature by EELS, TEM, STEM in both conventional and high-resolution imaging mode in an environmental TEM (Titan ETEM G2 80-300kV, ThermoFisher Scientific). After calcination under oxygen, the formation, evolution and distribution of networks of PdAu nanoparticles was followed in real time in order to monitor sintering processes and characterize the degree of stability of their organization.

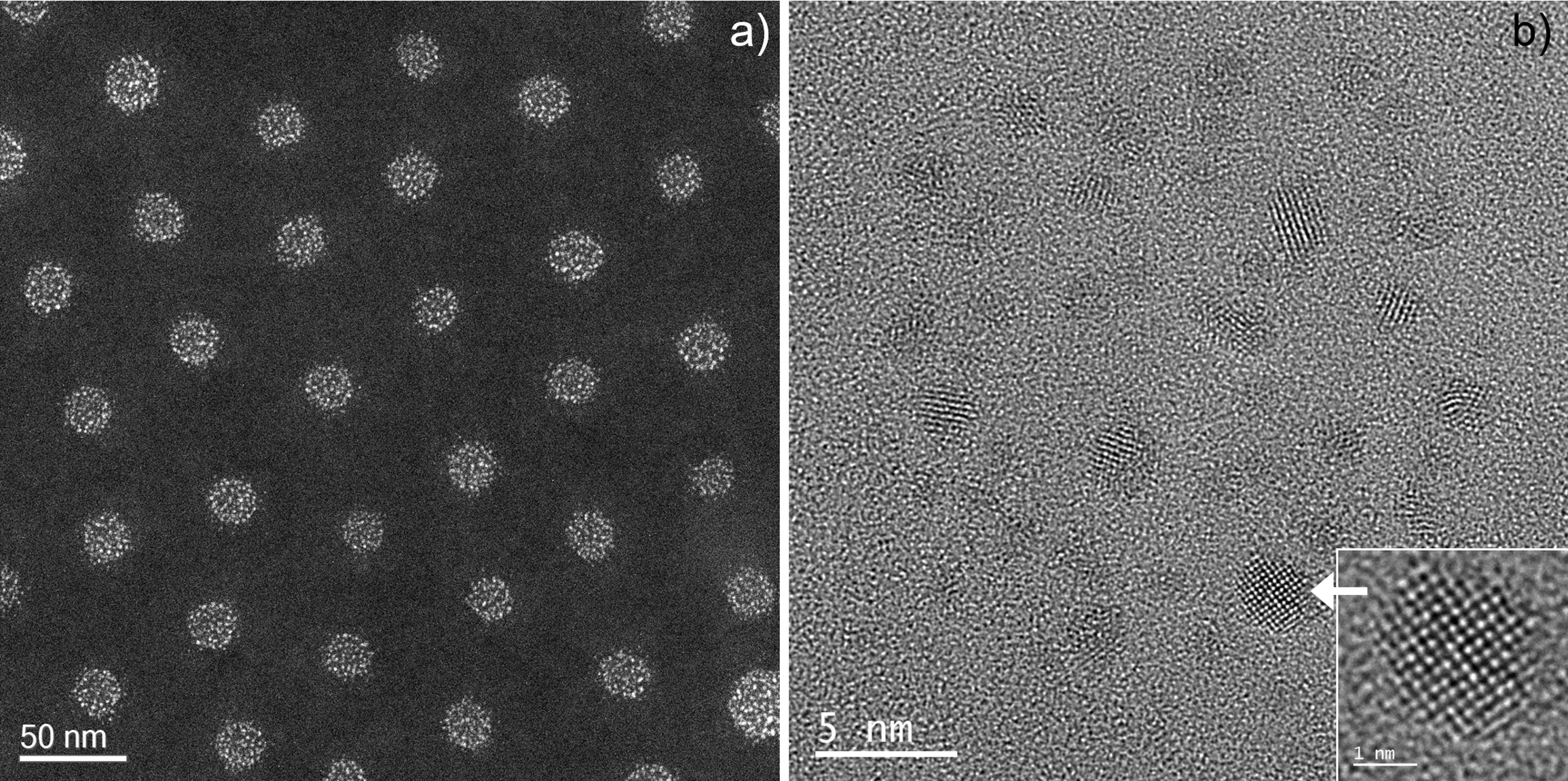

The (bi-)metallic seeds within the cores are about 1-2 nm in size, they have a chemical composition around Au0.6-08Pd0.2-0.4 and the inter-cores spacing was reasonably constant between 45 and 75 nm in the most homogenously distributed areas (see Figure 1).

Figure 1. Structure of the micelle film (20°C, high vacuum 8 10-7 mbar). a): low mag STEM image showing the pseudo-hexagonal organization of the micelle cores made of »1-2 nm AuPd nanoparticles. b): HRTEM image of a core; insert is a [001] oriented Au»80Pd»20 particle with {200} lattice fringes at 0.202 nm (ETEM 300 kV).

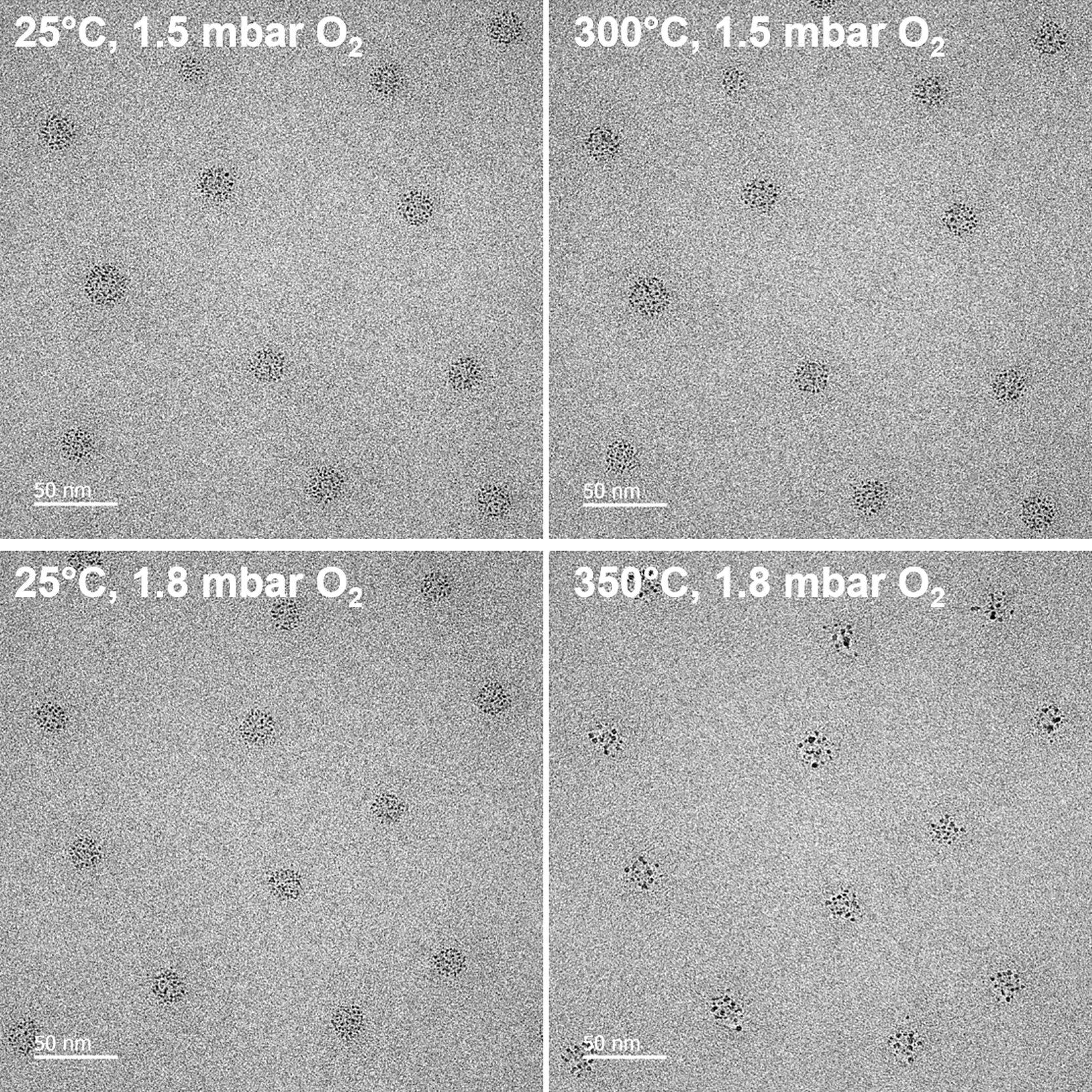

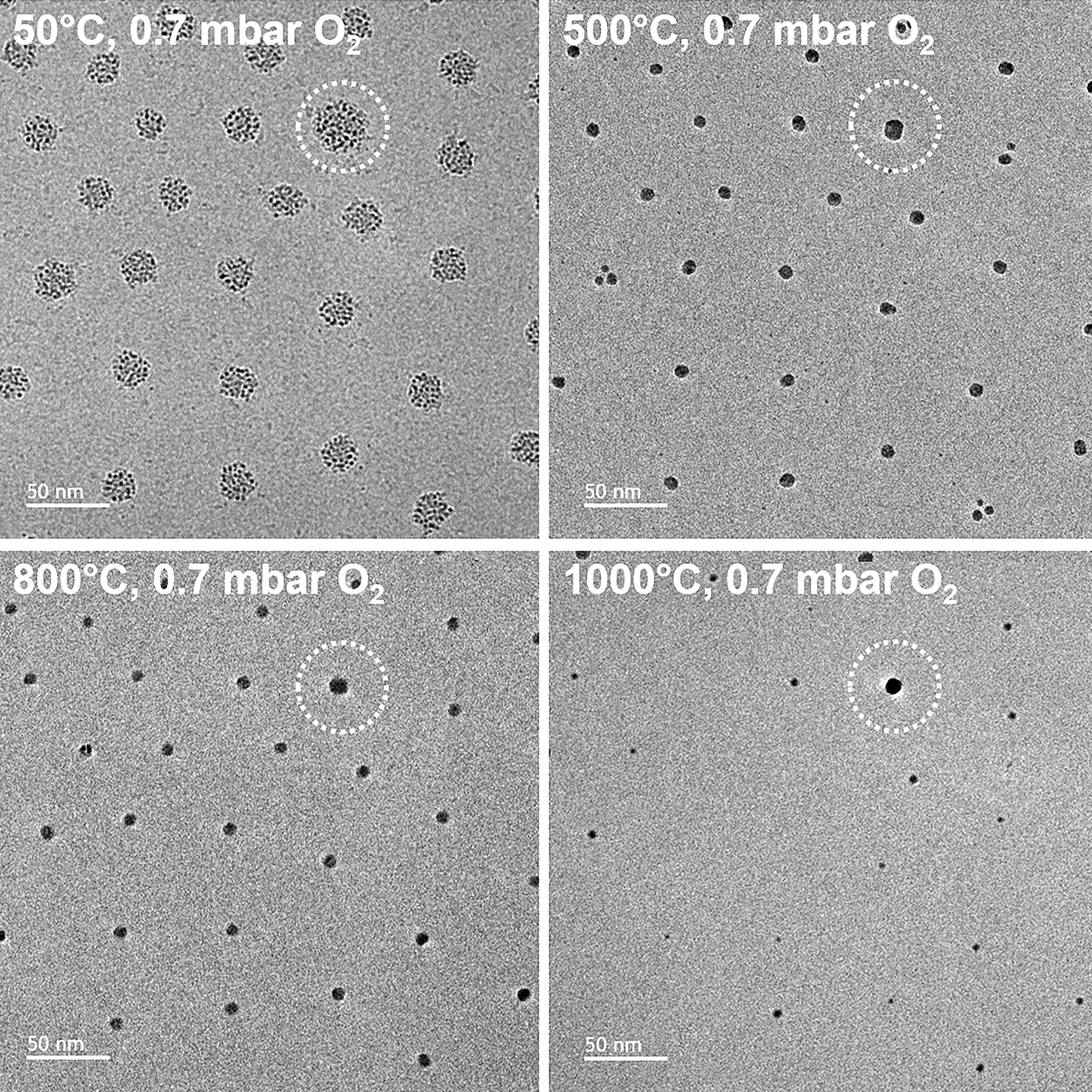

Treating the sample under oxygen (1.5 mbar) leads to the formation of multiple larger nanoparticles between 300 and 350°C as illustrated by Figure 2; they further coalescence into individual particles around 500°C. Their organization as a quasi-close-packed, roughly hexagonal network remains absolutely stable up to very high temperature, i.e. more than 800°C (Figure 3).

Figure 2. Evolution of the bi-metallic micelle cores in situ under oxygen. Top row: heating of a fresh area not exposed to the electron beam from 25°C (top left) to 300°C (top-right). Bottom row: same as before for a new fresh area heated up to 350°C. In both cases, the sample was maintained 60 seconds at the high temperature under beam blanking conditions (ETEM 300 kV).

Figure 3. Stability of the network of micelles cores followed in situ under oxygen; all observations were made after 30 seconds at each temperature (indicated), the beam being blanked during the heating steps (ETEM 300 kV). The dotted circle marks the same metallic core.

Alteration of this network only occurs above 1000°C when approaching the melting point of gold (1064°C). Very spectacular effects of the electron beam under oxygen were observed and properly controlled to draw out representative features of the behavior of the metallic nanoparticles as a function of temperatures [2].

- References

[1] E. Ehret et al., Nanoscale 7 (2015) 13239. DOI: 10.1039/c5nr02215k

[2] Thanks are due to the French Microscopy and Atom Probe network METSA (www.metsa.fr) for supporting this study. CLYM (www.clym.fr) is greatly acknowledged for the access to the Titan ETEM.