Environmental degradation of SiC fibre/BN/SiC matrix ceramic matrix composites studied by TEM and EELS

- Abstract number

- 84

- Presentation Form

- Submitted Talk

- Corresponding Email

- [email protected]

- Session

- Stream 1: EMAG - Spectroscopy & Advanced SEM

- Authors

- Lisa Toller-Nordström (1), Louise Gale (2), David Armstrong (1), Rebecca Nicholls (1)

- Affiliations

-

1. Department of Materials, University of Oxford

2. Rolls-Royce plc

- Keywords

Ceramic matrix composite, environmental degradation, TEM, EELS

- Abstract text

This study investigates the environmental degradation and formation of a glassy phase in SiC fibre/SiC matrix ceramic matrix composites with a BN interlayer.

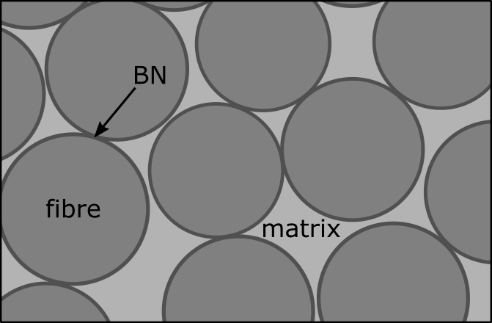

Reducing the emissions from airplane jet engines is an important step towards a future of cleaner air travel and transports. By increasing the turbine entry temperature the fuel efficiency can be improved, but at around 1100°C the superalloys used lose their strength, limiting any further increases in temperature. Ceramics retain their hardness at higher temperatures, but are instead limited by brittle fracture. Ceramic matrix composites, CMC’s, can be designed to mimic an increased fracture toughness compared to the individual ceramic materials, while still having retained hardness at high temperatures. The CMC’s are however susceptible to environmental degradation of interlayers, which may lead to failure of the component and has thus far limited their use. This work aims to increase the understanding of the degradation of SiC fibre/SiC matrix CMC’s with turbostratic BN interlayers, a sketch of the material can be seen in Figure 1.

Figure 1: Sketch of a cross section through the CMC’s used in this work.

The samples have been tested until failure in a tensile creep test in air at elevated temperatures. By focused ion beam, thin lamellae have been extracted from close to the fracture surface, which have then been studied by TEM, including SAD and EELS.

It was found that a new phase forms at the interface between the SiC and BN, the amounts of which appear to increase with increasing temperature. Initial investigation suggests that this phase consists of amorphous silica. Formation of a glassy phase increases the brittleness of the material, which then lead to a shorter time to fracture.

- References