High-Speed AFM as a Quality Control Tool: Measuring the Roughness Variability of SiC Monofilaments for Metal Matrix Composites

- Abstract number

- 156

- Presentation Form

- Poster Flash Talk + Poster

- DOI

- 10.22443/rms.mmc2021.156

- Corresponding Email

- [email protected]

- Session

- Poster Session 2

- Authors

- Mr Dhilan Devadasan (1), Mr Nathan Sutemire (1, 2), Dr Mark Baker (1), Professor John Watts (1)

- Affiliations

-

1. University of Surrey

2. TISICS

- Keywords

High-Speed AFM; SiC Monofilaments; Metal Matrix Composites; Quality Control; Large Data; Statistical Measurements; Roughness

- Abstract text

The coating system on silicon carbide (SiC) monofilaments, manufactured using a chemical vapour deposition (CVD) process, plays an important role in the reinforcement of metal matrix composites (MMCs). The interface between the matrix and the ceramic fibre is critical for the toughening mechanisms in MMCs. However, currently there are very few methods of testing how the coating will perform in the composite prior to MMC fabrication. One hypothesis is that the coating roughness may influence the fracture mechanics at this interface and therefore, the performance of the composite. Hence, the nanoscale roughness of these monofilaments and its variability is of interest.

There has been significant research comparing the roughness of fibres produced by different manufacturers or processes using AFM, however, few have investigated the variation from a single manufacturing process, particularly for quality control applications. The significant advances in image acquisition speeds over the years, in the evolution of HS-AFM from AFM, has enabled many measurements to be collected for the necessary statistical power to differentiate very similar samples.

In this paper, a batch of SiC monofilaments fabricated using identical CVD processes (for use as the reinforcement in MMCs) were characterised using HS-AFM to help identify whether a correlation could be seen between the roughness and the bend strain test results. The goal of the work is to demonstrate HS-AFM as a possible quality control tool, and additionally to identify whether the roughness was related to bend strain.

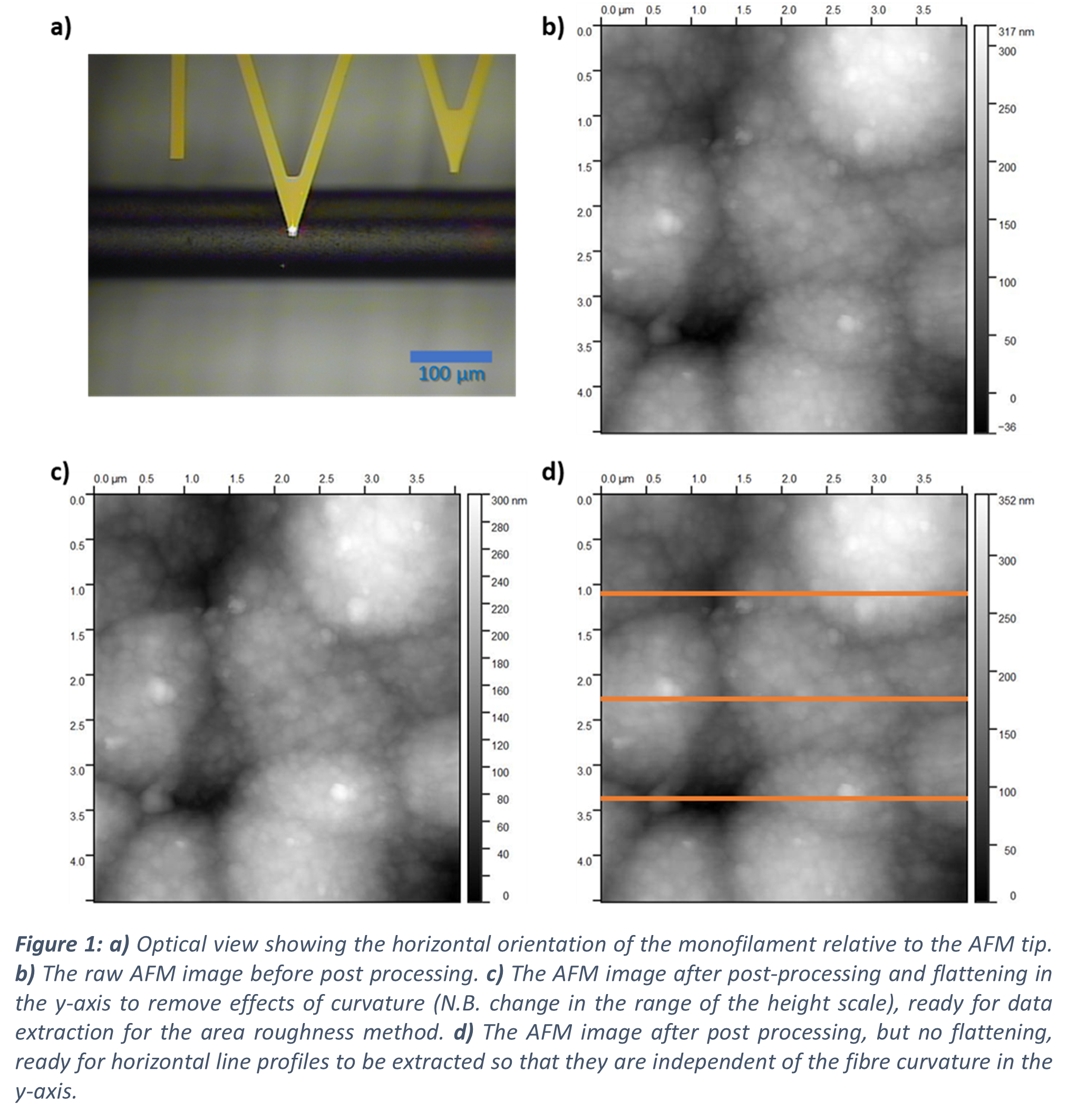

A Bristol Nano Dynamics HS-AFM was used to obtain high resolution 1000 x 1000 pixel images taken at 2 frames per second using a semi-automated, unbiased method that recorded measurements every 25 μm over lengths of several millimetres, resulting in hundreds of images for each fibre. Standard third-party software (Pygwy within Gwyddion) was used to post-process and extract roughness data. The limited 5 μm frame size, relative to the large 140 μm diameter monofilaments, in combination with the relatively large features, meant that it was impossible to detect the form of the fibre. Therefore, the paper analyses and compares two methods:

- Measuring area roughness parameters by first flattening the image to remove the background curvature (Figure 1c), retaining the 2D information of the surface;

- Measuring line roughness from horizontal line profiles obtained from each image to remain independent of the curvature (Figure 1d), at the cost of losing a large portion of the surface information.

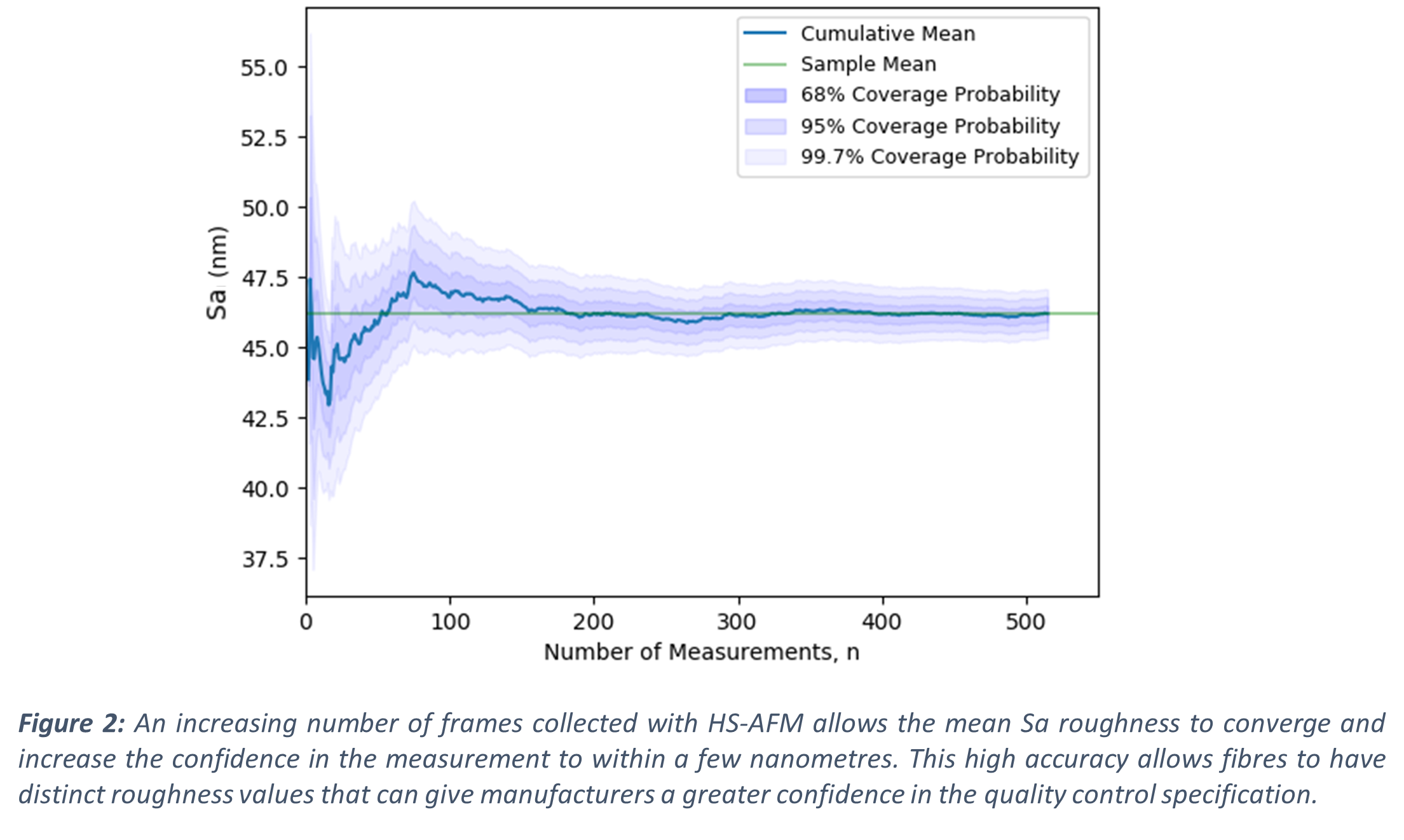

HS-AFM roughness data was tested to see how accurate and reliable it was (Figure 2) before being compared with the mechanical bend strain results using correlation tests.

A robust method of fibre characterisation has been demonstrated through the significant increase in the confidence of roughness mean values, as a result of hundreds of measurements. This increased accuracy and repeatability signifies that HS-AFM has the potential to be a useful quality control tool for statistical measurements of fibre roughness.

Bend strain results for each monofilament were obtained from the manufacturer’s in-house testing. These bend strain results had large uncertainties, and when plotted against HS-AFM roughness results, the correlation results were not totally conclusive, and further investigations are required.

On the basis of the statistical treatment of large datasets from this paper, and the superior image acquisition speeds, HS-AFM has a promising future in the field of quality control in material science.

- References

Vanswijgenhoven, E., Lambrinou, K., Wevers, M. & Van Der Biest, O. Comparative study of the surface roughness of Nicalon and Tyranno silicon carbide fibres. Compos. Part A Appl. Sci. Manuf. 29A, 1417–1423 (1998).

Chawla, N., Holmes, J. W. & Mansfield, J. F. Surface roughness characterization of NicalonTM and HI-NicalonTM ceramic fibers by atomic force microscopy. Mater. Charact. 35, 199–206 (1995).

Wastl, D. S., Weymouth, A. J. & Giessibl, F. J. Atomically resolved graphitic surfaces in air by atomic force microscopy. ACS Nano 8, 5233–5239 (2014).

Ražić, S. E., Čunko, R., Svetličić, V. & Šegota, S. Application of AFM for identification of fibre surface changes after plasma treatments. Mater. Technol.26, 146–152 (2011).

Clyne, T., & Withers, P. (1993). The interfacial region. In An Introduction to Metal Matrix Composites (Cambridge Solid State Science Series, pp. 166-217). Cambridge: Cambridge University Press. doi:10.1017/CBO9780511623080.007

Rix, M. Development of Silicon Carbide Monofilaments for the Reinforcement of Metal Matrix Composites. (University of Surrey, 2018).