Large area visualization of the Li distribution in lithium-ion battery electrodes using plasma FIB and SIMS

- Abstract number

- 196

- Presentation Form

- Poster

- DOI

- 10.22443/rms.mmc2021.196

- Corresponding Email

- [email protected]

- Session

- Poster Session 3

- Authors

- Dr. Yige Sun (1, 2), Dr. Gareth Hughes (1), Dr. Junliang Liu (1), Prof. Chris Grovenor (1), Prof. Patrick Grant (1, 2)

- Affiliations

-

1. Department of Materials, University of Oxford

2. The Faraday Institution, Quad One, Harwell Science and Innovation Campus

- Keywords

Plasma FIB, SIMS, EDX, lithium-ion battery, characterisation, cross-correlation

- Abstract text

Lithium ion batteries (LIBs) have become the dominant energy storage medium for portable devices over the last 30 years because of their high capacity, high round-trip efficiency, reasonable power and continuously decreasing cost. LIBs use an electrolyte containing Li-ions that permeates the positive and negative electrodes, and the porous polymeric separator between them. On charging the lithium ion battery, Li-ions are moved to and stored in the negative electrode (anode), usually by intercalation into the inter-planar spaces of particulate graphite; on discharging, the ions cross to the positive electrode (cathode) and are re-inserted into usually a lithium oxide-based particulate such as LiCoO2. Both particle-based electrodes have thicknesses in the range of 50 to 700 µm. As charge and discharge processes speed up to deliver fast-charging and high power respectively, modelling and low resolution measurements of the spatial distribution of ions (e.g. by NMR) have suggested that significant through thickness gradients in the local Li-ions concentration develop, and are responsible for the well-known decrease in capacity. This behavior places an upper limit on the practical electrode thickness and the available capacity at high charge/discharge.

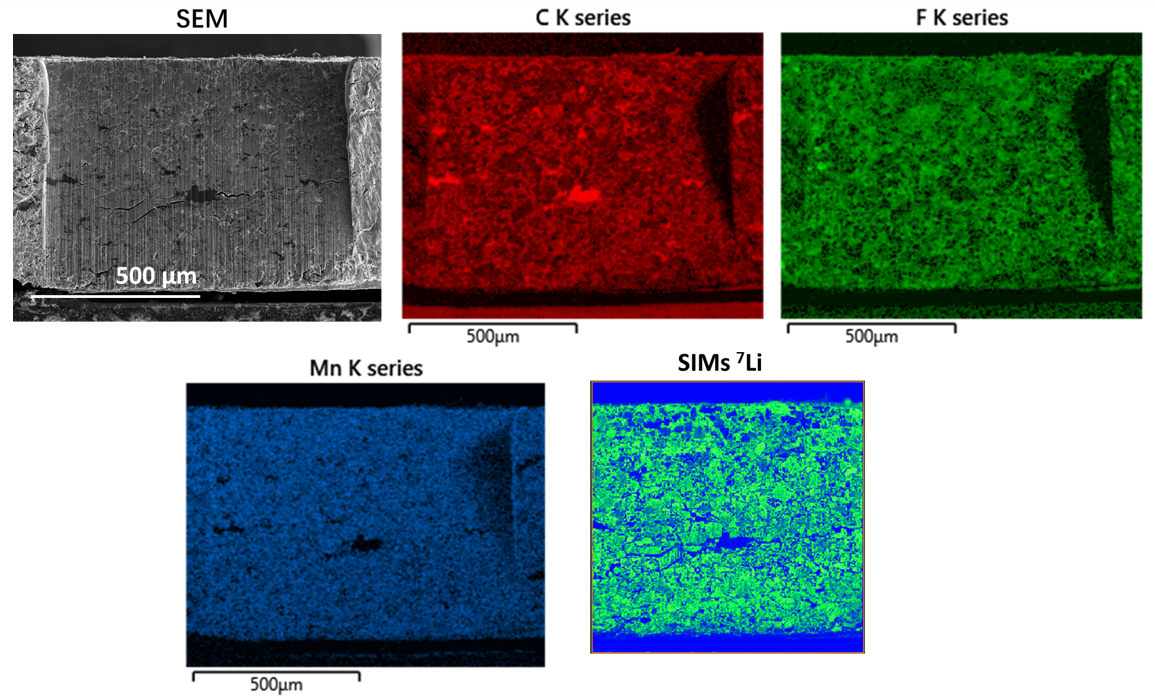

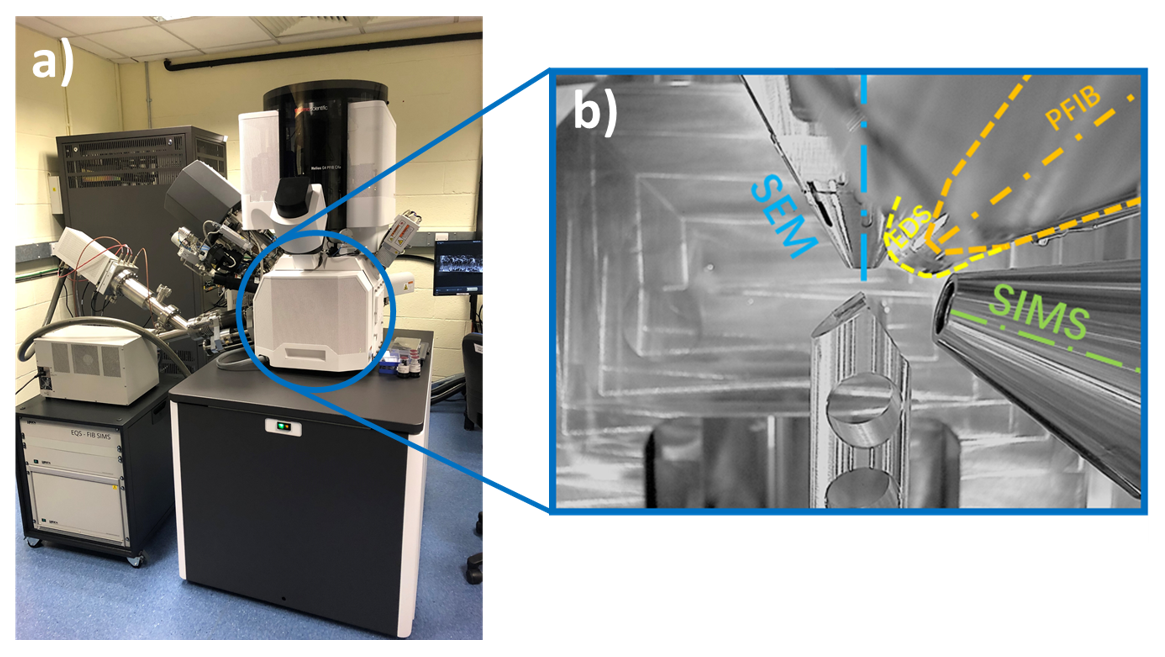

We describe the development of a methodology that allows the visualization of the distribution of key elements in a LIB electrode that ultimately aims to map Li gradients with high resolution and at the electrode scale. We selected a relatively thick (~ 700 µm) commercially available cathode and focused on the challenges of producing a cross-section and then mapping the spatial distribution of the key elements, including Li (Figure 1). For sectioning and polishing, we used a dual beam Xe plasma focused ion beam (PFIB, Thermo Scientific Helios, Figure 2). The relatively high current capability of the PFIB allowed milling of greater areas and volumes than conventional Ga-based FIBs, over shorter timescales and with less beam damage. The spatial distribution of most of the elements over the section surface was readily obtained by energy dispersive X-ray (EDX) analysis. However, the critical Li distribution is unavailable from EDX due to the low X-ray energy and low probability of emission. Therefore, we used secondary ion mass spectrometry (Hiden EQS SIMS) to obtain the spatial distribution of Li at similar high spatial resolutions.

Physically combining SEM/EDX and SIMS analysis in the PFIB required the use of a pre-tilt geometry, and the generation of new workflow protocols that combined milling and data capture using the two techniques. Post-experiment, new algorithms and image manipulation protocols were developed that allowed the merging of SIMS and EDX data, even though they were obtained at different resolutions and from only partially overlapping areas. Qualitative maps of the Li distribution are presented along with various element cross-correlation functions to identify specific phases in both 2D and 3D. Progress to date, advantages, restrictions, possible future uses and likely next developments of this analytical strategy will also be described.

Figure 1: SEM image, EDX and SIMS chemical maps of a lithium manganese oxide-based cathode cross-section.

Figure 2: (a) The Thermo Scientific Helios G4 Plasma FIB (PFIB) DualBeam system combining EDX and SIMS. (b) Inside the PFIB, showing the main columns and detectors.