Particle analysis of siliceous sand fillers in electrical insulating epoxy resin-based casting system using Environmental Scanning Electron Microscopy

- Abstract number

- 70

- Presentation Form

- Poster

- DOI

- 10.22443/rms.mmc2021.70

- Corresponding Email

- [email protected]

- Session

- Poster Session 3

- Authors

- Martin Olbert (1), Vilém Neděla (1), Josef Jirák (1)

- Affiliations

-

1. Institute of Scientific Instruments of the Czech Academy of Science

- Keywords

epoxy resin, ESEM, filler, image processing, particle analysis

- Abstract text

Epoxy resins are synthetic polymers, which belong to the group of thermosetting polymers. This type of resin contains epoxy groups in its chemical structure, which acquire important properties through chemical process called curing. Curing may be achieved by reaction of the epoxy resin itself, or by reaction with other chemical hardeners. Polymerization and formation of a cross-linked three-dimensional structure occurs after reaction with a specific hardener. Cured epoxy resins have very good mechanical strength, chemical resistance, dielectric and electrical insulating properties. To improve some of these properties, mineral fillers, like siliceous sand fillers, are added to the curing process. Homogeneous dispersion of the filler is crucial for proper function of the entire system. Hence, sedimentation of bigger particles of filler can be a serious problem. The resins have a wide range of applications, from adhesives, coatings, potting compounds to electrical systems, insulators and electronics. [1, 2, 3]

The environmental scanning electron microscope (ESEM) and subsequent image-analysis are helpful and effective tools to control the exact distribution of the filler. Images of different locations of the cured system can reveal possible sedimentation, agglomeration, and heterogeneous distribution of the filler.

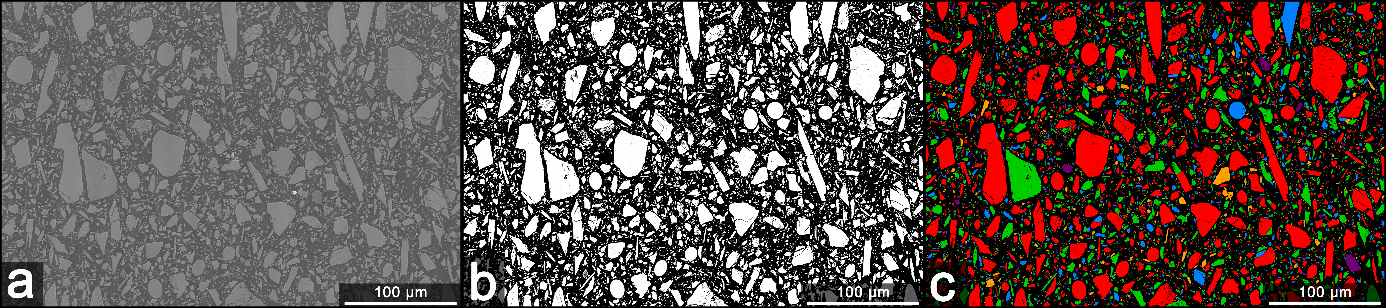

We observed specific parts of the resin, where the filler could aggregate or sediment. These parts were cut from the whole sample and polished. Subsequently, images were taken at low pressure of water vapor using ESEM. ESEM allows direct observation of electrically non-conductive samples without charging artefacts [4], which is crucial in this work. The presence of artefacts would significantly distort the accurate analysis and evaluation of the acquired images. The next step was the image analysis using software MountainsMap® SEM Topo. For this reason the „Binary thresholding“ method was used. This method consists of the detection of filler particles from the background (from signal contrast between particle/background). To obtain more accurate detection, we increased the contrast in the intermediate step. The software then allows to display numerical distribution of particles, according to the selected parameter. In this case, selected parameter was „particle size“, which is defined as the maximum diameter of the particle passing through its center of gravity. The steps of the image particle analysis are shown in Figure 1.

Figure 1.: The process of particle analysis. In a) ESEM image of polished surface of uncoated epoxy resin, b) contrast adding to improve evaluation, c) marking of all filler particles.

The particle size distribution expressed as a percentage of the total number of particles analyzed in images at various locations was evaluated. The results showed, that the fillers were homogeneously distributed throughout the system, and that no sedimentation or agglomeration occurred. Homogeneous distribution of the filler provides quantitative information about this system which can be used as one of the validation tools of the curing procedure quality.

This particle analysis method has a wide range of applications. We can measure percentage size distribution and other physical properties of microparticles inside various systems and materials. Moreover, we can analyze these parameters in the pure fillers and powders themselves. ESEM is a crucial technique in this type of analysis for several reasons. It enables us to obtain images without any charging, image degradation and other artefacts. Another indisputable advantage is the possibility of scanning the sample without any previous surface treatment. All this benefits significantly reduce the risk of incorrect particle analysis and at the same time they increase measurement accuracy. [5]

- References

[1] T. Imai, F. Sawa, T. Nakano, T. Ozaki, T. Shimizu, M. Kozako, T. Tanaka, IEEE Transactions on Dielectrics and Electrical Insulation IEEE, vol. 13, (2006), p. 319 - 326.

[2] L. Harvánek, T. Tomášková, V. Mentlík, P. Trnka, 16th International Scientific Conference on Electric Power Engineering (EPE), (2015) pp. 346-349.

[3] J. Mleziva, J. Šňupárek, Polymery - výroba, struktura, vlastnosti a použití, 2. edition. Prague: Sobotáles, (2000), 537 p. ISBN 80-85920-72-7.

[4] A.M. Donald, Nat. Mater. 2 (2003) 511–516.

[5] The project was supported by the Grant Agency of Czech Republic GA 19-08239S and GA 19-03909.