Understanding the role of oxygen in titanium alloys for use in jet engines.

- Abstract number

- 52

- Presentation Form

- Submitted Talk

- DOI

- 10.22443/rms.mmc2021.52

- Corresponding Email

- [email protected]

- Session

- Stream 3: Advanced Atom Probe Tomography

- Authors

- Dr Hazel Gardner (1), Dr Anna Radecka (2), Prof David Rugg (2), Dr David Armstrong (1), Prof Michael Moody (1), Dr Paul Bagot (1)

- Affiliations

-

1. Department of Materials, University of Oxford

2. Rolls-Royce plc

- Keywords

Titanium alloys, aerospace, atom probe tomography, oxidation

- Abstract text

Titanium alloys are used to make jet engine fan blades and compressor discs. The high specific fatigue strength of titanium alloys means that total engine weight can be reduced by maximising the use of titanium-based materials. However, even trace amounts of oxygen can embrittle titanium alloys [1]. Furthermore, temperatures above 480oC enable diffusion of oxygen through the protective oxide surface layer on titanium components. This high level of oxygen ingress forms a detrimental, brittle subsurface layer that is often referred to as ‘alpha case’[2], which restricts use of titanium alloys to temperatures below ~600oC.

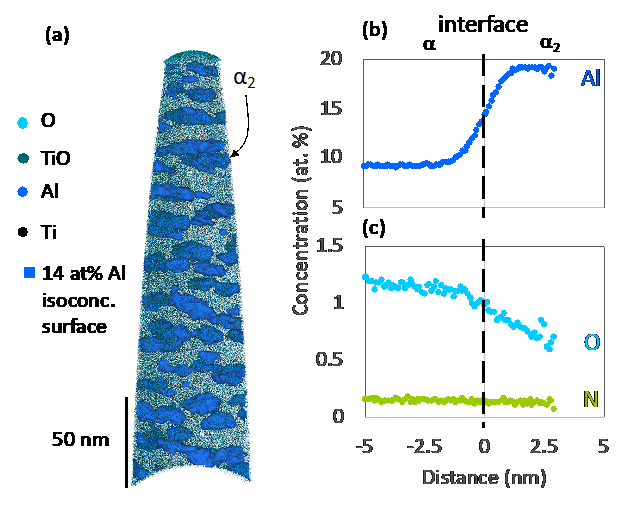

Despite the significant detrimental effect of oxygen on the mechanical properties of titanium alloys, the location of oxygen within the microstructure and the role oxygen plays in embrittlement mechanisms is not well understood. This work uses the combined high spatial resolution and chemical sensitivity of atom probe tomography to map and quantify both trace and high levels of oxygen within titanium alloys on the nanoscale. Particular attention is paid to the interaction of trace amounts of oxygen with the embrittling α2 phase, seen in figure 1, to understand the role of oxygen in its formation. Complementary use of nanoindentation, electron backscattered diffraction and electron microprobe analysis provides insights into the effect of crystallography and microstructure on high levels of oxygen ingress, and the resultant effect on mechanical properties.

An overview of the effects of both trace and high levels of oxygen on mechanical properties of a range of titanium alloys is presented, through careful mapping and quantification of oxygen within the microstructure. This information can be used to inform alloy processing and design by providing an improved fundamental understanding of the role of oxygen in titanium alloys.

Figure 1: APT atom map with 14 at. % Al isoconcentration surfaces highlighting α2 precipitates in (a) Ti-7Al + 2500 wppm O, 49 day aged. Concentration profiles across the α matrix- α2 precipitate interface showing the partitioning behaviour of (b) Al and (c) O and N with respect to the precipitates.

- References

[1] Q. Yu, R. Traylor, D. Rugg, M. Asta, D. C. Chrzan, and A. M. Minor, Science (80-. )., vol. 347, no. 6222, pp. 635–640, 2015.

[2] R. Gaddam, B. Sefer, R. Pederson, and M.-L. Antti, IOP Conf. Ser. Mater. Sci. Eng., vol. 48, p. 012002, 2013.